CAMX 2022 exhibit preview: Qarbon Aerospace

Qarbon Aerospace exhibits its capabilities in manufacturing composite components and assemblies, highlighting its proficiencies in major assembly and systems integration, automated layup, hand layup, high-temp composites and core fabrication.

Qarbon Aerospace (Red Oak, Texas, U.S.) is a manufacturer of composite components and assemblies at all levels of complexity with products installed on commercial, military and space aircraft. Qarbon says it leverages its experience in composites manufacture, large structures assembly and thermoplastic technologies to partner with customers in design optimization to produce defect free, on-time deliveries at optimum value. The company’s manufacturing capabilities include:

- Major assembly and systems integration: Includes wings, vertical and horizontal stabilizers, tail sections, nacelles and fuselage sections for fixed- and rotary-wing aircraft.

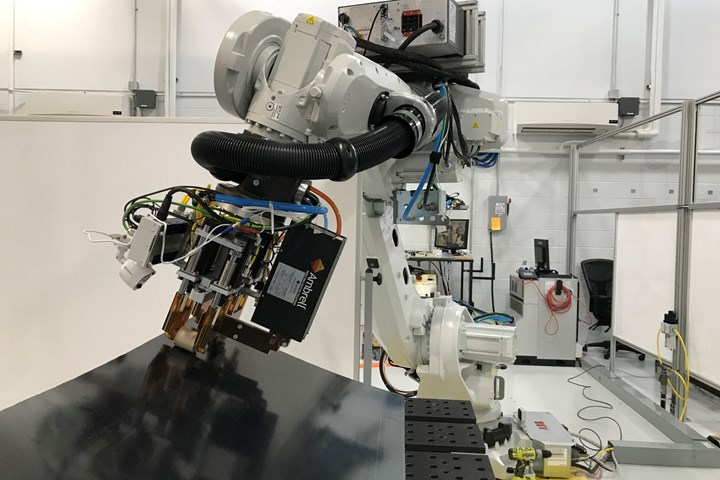

- Automated layup: Qarbon’s climate-controlled areas (CCA) are equipped with three- and five-axis automated tape laying (ATL), an automated stringer machine, same-qualified resin transfer molding (SQRTM) and fiber tow placement machines.

- Hand layup: Qarbon says its CCAs meet stringent air quality requirements. All CCAs are fitted with the latest technologies in overhead ply projection systems and debulk stations.

- High-temp composites capabilities: Service temperatures up to 700°F (371°C) are possible, with autoclaves up to 800°F, pressure up to 200 psi and ovens up to 1,000°F available.

- Core fabrication: In-house core machining and forming, enables Qarbon to control cost and lead time with multiple five-axis core milling centers, Nomex and aluminum core forming, hot die forming and pin routing.

In addition to its manufacturing capabilities, Qarbon Aerospace also highlights its technologies in thermoplastic composites. Both technologies are ready for launch platform applications. Qarbon’s induction welding of uni-directional (UD) carbon fiber tape enables for capabilities in dissimilar thick joints, blind one-sided welding and high-curvature part performance. In addition, Helios Ice Protection is an electro-thermal icing protection system offered by the company.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.