Coriolis highlights C1.2 compact AFP system for multi-material applications

New developments regarding productivity, maintenance and ergonomics make this enhanced composite placement system well suited for the production of complex parts.

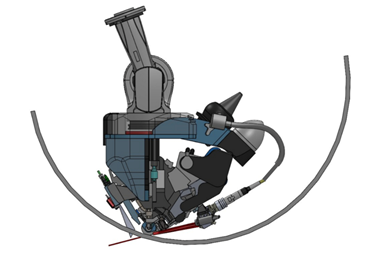

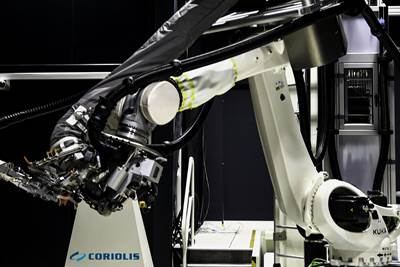

Coriolis Composites (Quéven, France) has been providing the C1.2, a compact, easy-to-use and versatile machine for depositing multi-materials (thermosets, thermoplastics and dry fiber), since the end of 2022. The result of long observation and experience based on nearly 80 Coriolis C1 machines in operation globally since 2010, the C1.2 automated fiber placement (AFP) system is available in two options: able to place 8 or 16 tapes/tows (¼-inch-wide).

The C1.2 features optimized head compactness, increased productivity and reliability, improved maintainability and a focus on its footprint and sustainability, further detailed below.

The C1.2 maintains the compactness of its predecessor, which has made C1 machines successful for complex parts. For example, the C1.2 can fit into 1-meter-diameter concave tooling. According to Coriolis, the C1.2 8 fibers version is even more compact so it can address 45° ramps. The compactness of the 16 fibers version has also been optimized.

Maintenance for routine operations on the head can now be carried out without tools. The duct support frame (which holds the guide duct) has been lowered for easier management. Duct balancers are accessible directly from the ground. The in-line Multiwinch reduces fiber tension for snag-free passage in the guide duct. Each cutting blade can also achieve up to 100,000 cuts, which significantly reduces blade changes.

One of the more major developments is the C1.2’s ability to achieve higher layup speeds — up to 1 m/s when feeding and cutting, and more than 1.5 m/s during layup — with improved reliability. This gain in speed is explained by the use of motorized modules in the creel accommodating fiber spool up to 15 kg of raw material, i.e. three times more material on board combined with controlled management of the dancing arms, which improve the unwinding of the material. Three infrared lamps are supplied as standard for additional speed. Additional time savings are achieved via link paths in the case of alternating layups, mainly for 0º plies. The equipment also makes it possible to obtain cleaner, straighter fiber cuts, even at high speeds, and better feeding. The C1.2 can also use very thick materials, further enhancing productivity.

To evaluate overall C1.2 process reliability, Coriolis performed a mean strip before failure (MSBF) test at high velocity. This performance and reliability test was done with more than 30,000 cuts per blade through 144 small panels (18 mm thick) made of feeds and cuts separated by 2-mm gaps. The 8 fibers machine resulted in an MSBF value of 15,000.

Finally, the AFP robot has been better integrated into the rail, and the creel can be accessed without a platform, thus reducing the footprint of the AFP enclosure, and improving overall cell ergonomics. Compaction pressure is now an advantage for reducing porosity during the in-situ deposition of thermoplastics. To address current environmental challenges, the process remains light and energy efficient compared to more massive and heavy solutions. The C1.2 is also compatible with in-line inspection solutions (AIS) developed by Coriolis and is suitable for mounting compact laser optics.

The C1.2 is a versatile machine for multi-material applications in R&D. Coriolis also has a range of machines with interchangeable heads for larger and less complex parts, including the Coriolis C3 and C5.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreRead Next

Coriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More