Huntsman epoxy, polyurethane resins designed for aero, auto, wind

Huntsman Advanced Materials is showcasing applications of its resin systems for the automotive, aerospace, wind energy markets.

Source | Huntsman Advanced Materials

Editor’s note: CompositesWorld received several new product and technology announcements ahead of JEC World 2020, which had been scheduled for March 3-5. Although that exhibition was postponed to May, CW is now publishing the announcements we received. This is one of them.

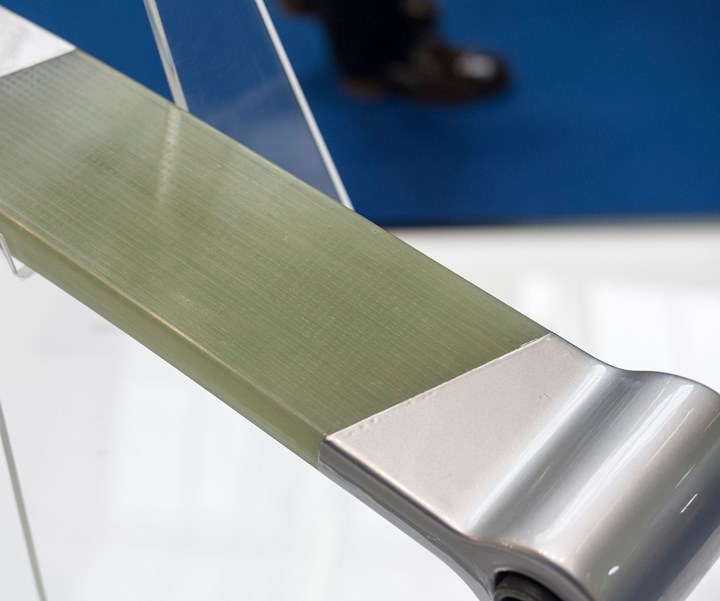

Resin technologies specialist Huntsman Advanced Materials (Basel, Switzerland) is showcasing pressure vessels based on ARALDITE composite solutions with high thermo-mechanical performance, as well as leaf springs using its ARALDITE epoxy resin system and VITROX RTM polyurethane resin system.

Huntsman is also featuring its RIMLINE HC+ polyurethane resin system, which is said to enable production of ultra-lightweight automotive interior components from fiberglass-reinforced material, and its new RIMLINE FC rigid foam technology for composite cores. For e-mobility, Huntsman is displaying several applications of potting and encapsulating resins, which provide improved thermal capabilities.

For the wind energy, marine and outdoor assembly industries, Huntsman is showing applications of its latest acrylic adhesives, including a wind blade repair application using ARALDITE 2050 epoxy resin, a product which can be applied in extreme low temperatures, enabling a downtime reduction of up to 50%, and a mock-up sandwich panel structure for boat-building utilizing the non-sagging, high gap-filling ARALDITE 2023 epoxy resin.

Also featured, Huntsman’s new EPIBOND epoxy adhesives were developed to meet changing engineering, regulatory and economic requirements within the aerospace industry. EPIBOND 215 A/B structural adhesive can reportedly replace up to five competitive adhesives. For vertical and overhead applications, EPIBOND 200 A/B epoxy adhesive, also on display, is said to lead thermo-mechanical performance.

Economy-class airline seats illustrate ARALDITE FST 40002/40006 composite, a ready-to-use solution for cost-effective manufacturing via direct processes of aerospace interior composite parts.

Finally, Huntsman is unveiling a new electrically conductive adhesive modified with MIRALON carbon nanotube materials, and is demonstrating its CNT-based MIRALON sheets that can be embedded in composite structures, such as heat-generators, and require very low voltage.

Related Content

-

RTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

.jpg;width=70;height=70;mode=crop)