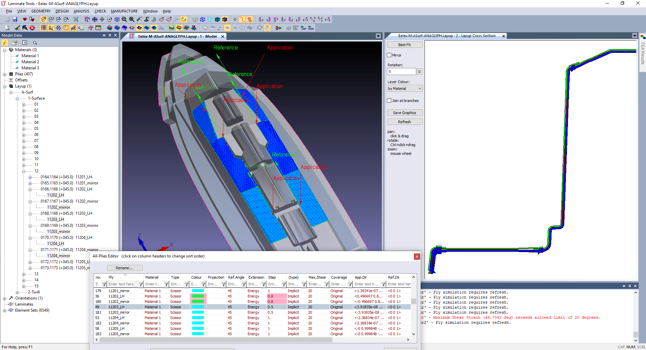

Laminate Tools version 5.1 supports new and optimized user-driven functions

The new version release of Anaglyph’s composite design software offers an extensive list of feature improvements and enhancements to its Design, Check and Manufacture modules.

Photo Credit: XShore Production AB, Sweden

Anaglyph Ltd. (London, U.K.) has released a new version of its Laminate Tools software, a standalone Windows application for composites design, analysis and manufacturing. Version 5.1 builds on the features introduced with version 5, improves functionality and stability and further enhances the capabilities of the software, according to the company. A number of user-driven functions in the Design, Check and Manufacture modules have been added.

A few notable overarching features include:

- More efficient, speedy response to user actions.

- Adaptation of the user interface for use with PlyMatch hardware, as with earlier versions.

- Added support in postprocessing for Abaqus versions 2022 and 2023.

A complete and extensive list of new features can be found here.

Laminate Tools addresses the entire Design-Analysis-Check-Manufacture group process of structural design, but focuses on composite material features. It consists of six modules: View, Geometry, Design, Analysis, Check and Manufacture. The View module exhibits read-only viewing functionality that enables easy, in-depth examination and understanding of the composite design. The other five modules extend the product’s outstanding functionality by importing surface geometry, creating Ply and Layup material information, FE laminate properties, checking FEA stress results, generating failure indices, exporting Ply patterns and enabling information flow between third-party applications.

Laminate Tools is reported to offer the benefit of a flexible workflow, as it has native interfaces to Nastran, Ansys, Abaqus, HyperMesh, OptiStruct, SolidWorks, Rhino and can communicate with most CAD and FEA applications via industry standard file formats.

Related Content

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.