The Gill Corp. announces hybrid laminate for aircraft cargo flooring

Gillfab F433F is a fiberglass-reinforced epoxy laminate with aluminum bonded faces, offering enhanced durability, fire resistance and strength.

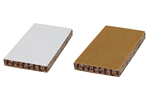

The Gill Corp. (El Monte, Calif., U.S.) introduces Gillfab 5433F, a lightweight hybrid laminate material designed specifically for the rigorous conditions found in aircraft cargo areas. The material features aluminum faces bonded with an epoxy laminate, fortified by woven fiberglass, providing optimal resilience in high-traffic zones such as around cargo doors and within bulk cargo sections.

According to the company, Gillfab 5433F is engineered to be highly resistant to physical damage, including dents, punctures and abrasions, to provide enduring performance under tough conditions. Moreover, it offers improved load-bearing capacity, maintaining structural integrity even when subjected to heavy loads. Enhanced aircraft safety is achieved by retarding fire spread, providing crucial additional time for emergency procedures; Gillfab 5433F meets the stringent requirements of FAR 25.853 and 25.855 Appendix F Part 1, thereby meeting aviation industry standards for safety and performance.

Related Content

-

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Owens Corning initiates review of strategic alternatives for glass fiber business

Owens Corning considers alternative options like a potential sale or spin-off as part of its transformative move to strengthen its position in building and construction materials.