Search Results

Showing 431 – 440 of 1112 results

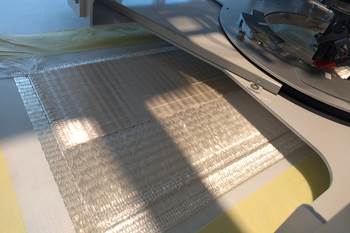

Composite materials are engineered combinations of two or more distinct materials, merging their individual properties to create a new material with enhanced characteristics. Typically composed of a reinforcing phase (like fibers or particles) embedded within a matrix (often a polymer, metal, or ceramic), composites leverage the strengths of each component to achieve superior strength, stiffness, lightness, or other desirable attributes. Their versatility extends across industries, from aerospace and automotive to construction and sports equipment, where their tailored design and exceptional properties offer solutions for high-performance applications.

Recycling in composites manufacturing is an evolving endeavor aimed at addressing sustainability challenges. Unlike traditional materials, composites often pose recycling complexities due to their multi-component nature. However, innovative techniques are emerging to tackle this issue. Methods like pyrolysis, mechanical recycling, and chemical processes are being developed to efficiently recover valuable components from composite waste, such as fibers or matrix materials.

The flax fibers meet strength and stiffness requirements while reducing vibration, cost, enhancing safety and lowering its CO2 footprint by 75%.

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

The 17th-annual Carbon Fiber conference is just weeks away (Dec. 8-10) and it's time to register if you haven't done so. This year's conference marks the return of Chris Red's carbon fiber supply and demand report, and we will also hear from Boeing's director of 777X wing manufacture.

The carbon fiber RTM press will be installed at the CSP facility in Palmela, Portugal in order to run the company's first commercial applications using this technology.

Scout Boats and now Hinckley Yachts showcase how demand for lighter, faster performance pushes materials and process change.

ThermoPRIME and Thermosaïc technologies recycle plastic and composite waste via modular, flexible equipment.

European project dedicated its first year to sustainable materials development and prototype manufacture, looks to validating performance.

Life Cycle Assessment (LCA) finds Covestro’s Maezio continuous fiber-reinforced thermoplastic composites can significantly reduce carbon footprint for laptop applications.

AeroLas is working to combine recycled carbon fiber with PEEK using adapted art textile machines and a patented air guided ring spinning technology.

Designers are invited to submit a product, part, or concept that uses KyronMAX’s range of high-strength, carbon fiber-based composites for a $25,000 prize and prototype development support.