Plant Tour: BENTELER SGL, Ort im Innkreis, Austria

High-volume CFRP structures pioneer makes industrialization and multimaterial assembly look easy.

Share

Long before “snap-cure” resins and high-pressure resin transfer molding (HP-RTM) became composites industry trends, BENTELER SGL (Ried im Innkreis, Austria) was forging a path away from hand-laid prepreg toward more automated processing of composite components for production automobiles. Since its beginnings, in fact, RTM has been firmly embedded in the company’s DNA.

BENTELER SGL is located alongside aerocomposites powerhouse FACC (see FACC AG: Aerocomposites Powerhouse). Both evolved from ski manufacturer Fischer GmbH, which launched its RTM-based Vacuum Ski technology in 1985. Fischer Composite Technology (FCT) was spun off in 2001 and began production of RTM “hang-on” parts for Porsche (Stuttgart, Germany) the following year. FCT was acquired in 2009 by the BENTELER SGL joint venture, established in 2008 between BENTELER Automotive (Paderborn, Germany) and SGL Group (Wiesbaden, Germany).

Beyond its history of innovative composites production, BENTELER SGL is itself a unique composite of automotive and carbon fiber expertise. BENTELER Automotive develops and produces components and modules for chassis, body and engine/exhaust systems as well as systems solutions for newer technologies, such as electric vehicles. SGL, one of the world’s leading industrial-grade carbon fiber manufacturers, created with BMW AG (Munich, Germany) the supply chain that now supports the latter’s volume production of carbon fiber-reinforced plastic (CFRP) vehicle structures (see BMW Leipzig: The epicenter of i3 production). True to the definition of a composite, however, both companies have retained their distinctive characteristics and strengths within BENTELER SGL. Each has a managing director co-leading the joint venture and each fully supports the company with its broad resources and acumen. The resulting autocomposites production offers capabilities that exceed the sum of its partner companies.

Automated, industrialized composites

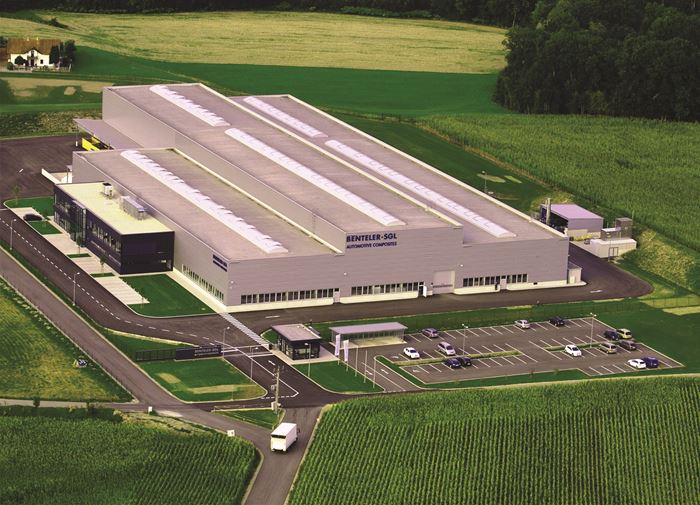

BENTELER SGL headquarters are in the original Ried im Innkreis FCT plant, now expanded to 7,000m2 and automated for prototyping new production processes (Fig. 6). Although low- to mid-volume production is still accommodated there, CW toured only the production facility in Ort im Innkreis. The Ried site is typically not open to visitors, because the large 2,000m2 Technical Center frequently has confidential projects running. During CW’s visit, a new hoodset for a premium automotive OEM was being ramped to full-rate production.

The Ort facility tour begins in its upstairs offices and conference room, hosted by BENTELER SGL’s joint managing directors. Helmut Ascher came to BENTELER SGL from BENTELER Automotive in 2014, having served there as a plant manager since 2003, most recently for aluminum structures in Holland, MI, US, and then as an executive VP at BENTELER Automotive in Paderborn, Germany, from 2010. Robert Ernst-Siebert came to BENTELER SGL in 2015, having been with SGL since 2007, first as a market analyst for new business development, then as product manager for ceramic composites and, subsequently, director of sales for carbon fiber and composites.

Built in 2012, the 10,000m2 Ort im Innkreis facility sits on a 42,000m2 site that offers room to expand, including additional surrounding acreage. “We are not a company that produces 10 to 100 parts,” Ernst-Siebert points out. “We are the leading company in terms of high-volume composite components via automated production, and we offer a full supply chain, from fibers to painted parts.”

Ascher notes that daily business operations are integrated with BENTELER Automotive, “so we understand and are geared to automotive production standards.” He adds that proficiency in how to ramp production “enables us to be a bit faster, if new materials are required. This is also because SGL is more than a supplier, adjusting materials and completing required development and testing. This makes a difference in our capabilities and speed.”

Despite the SGL connection, however, not all production at BENTELER SGL involves carbon fiber reinforcement. One of its signature products, in fact, automotive leaf springs, are reinforced with glass fiber. “We always look to select the right technology, which fits best with respect to targeted properties, production volume and cost,” says Ernst-Siebert. This applies not only to reinforcements but processes as well. BENTELER SGL production has used woven and noncrimp fabrics (NCF), tailored fiber placement preforms (see Tailored Fiber Placement: Besting metal in volume production), braiding and filament winding.

Automating and scaling manufacturing to fit parts and programs is really the essence of BENTELER SGL. “Our core competencies include product and process development and automated preforming,” notes Ascher. “We are also a leader in RTM and wet pressing, enabling us to produce high volumes with short cycle times.” Additional areas of expertise include prepreg pressing, sheet molding compound (SMC), adhesives technology, CNC machining and assembly.

Gallery of structures

From upstairs, the tour heads downstairs and through a composite parts gallery on display in the building lobby. A CFRP seat for the BMW M3 CRT features two preforms that use recycled carbon fiber and a paper honeycomb core. A rear decklid for the Porsche 911 GT3 integrates a rear spoiler/wing and at least 10 other major components into a fully finished, Class A painted part delivered to the OEM production line (Fig. 2).

Next is a CFRP-reinforced steel B-pillar, part of a prototype qualification program with an OEM, which developed BENTELER SGL’s Hybrid Patch Process. Capable of producing A- and B-pillars, front walls, door trunk beams and sills, this process uses an automated preforming-and-cutting cell to build tailored prepreg patches — from both glass and carbon reinforcements — which are then pressed and cured onto prefinished steel parts.

Adjacent is a U-shaped CFRP front-end strut brace developed with BMW. The brace features structural sandwich construction, produced using RTM and polyurethane resin. Another strut brace BENTELER SGL developed for this customer also uses a braided preform and delivers high strength and stiffness, but features epoxy resin, a Class A “clear carbon” surface and hybrid construction — bonded to aluminum. “We have more than several parts in production for the BMW i3 and i8 models,” says Ascher, “for structural components.”

This theme of complex, multi-material assemblies is illustrated again in a chassis module for a major OEM, which replaces steel with glass fiber-reinforced plastic (GFRP) for weight savings. “BENTELER can make the whole assembly, including the GFRP leaf springs,” Ascher notes.

A rocker/A-pillar for Lamborghini (Saint’Agata Bolognese, Italy) comprises an upper and lower structure, the latter integrating two CFRP parts made with braided carbon reinforcements and a meltable wax core to create hollow parts that are light yet able to withstand impact and deliver key performance in crash testing (Fig. 2). Ascher says the epoxy RTM process is low volume, “but very complex. The issue is managing CTE [coefficient of thermal expansion] in this larger part, so the cure must be a bit longer vs. HP-RTM.” The upper and lower pieces are joined with epoxy adhesive. “This was a good project for us from a learning point of view,” he explains. “We use these projects to build our expertise.”

The gallery tour finishes with a CFRP door module in production since 2013, used for the Porsche 911 GT3 and one other model, and a foam-cored CFRP spare wheel well developed as a demonstrator for a high-end OEM (Fig. 3). Featuring complex geometry and formed in one shot, using RTM, the part uses foam core to impart stiffness and reduce noise, vibration and harshness (NVH), the latter an added function driving new composites applications in multi-material structures. “The original SMC solution did not provide sufficient NVH,” Ascher explains.

Leaf spring production

As the tour exits the lobby, it proceeds through a door midway along the southern wall of the massive production hall. As he leads the tour through an assortment of CFRP parts being readied for shipment and an array of gluing jigs used to produce parts for Audi, Ascher explains that the building is split between leaf spring production to the left and CFRP production on the right. The former consumes roughly one-third of the hall, comprising automated manufacturing cells for Daimler springs and a much larger production line, which has produced more than 500,000 composite leaf springs per year since 2015, for all Volvo vehicles that are based on the new Scalable Product Architecture (SPA) platform.

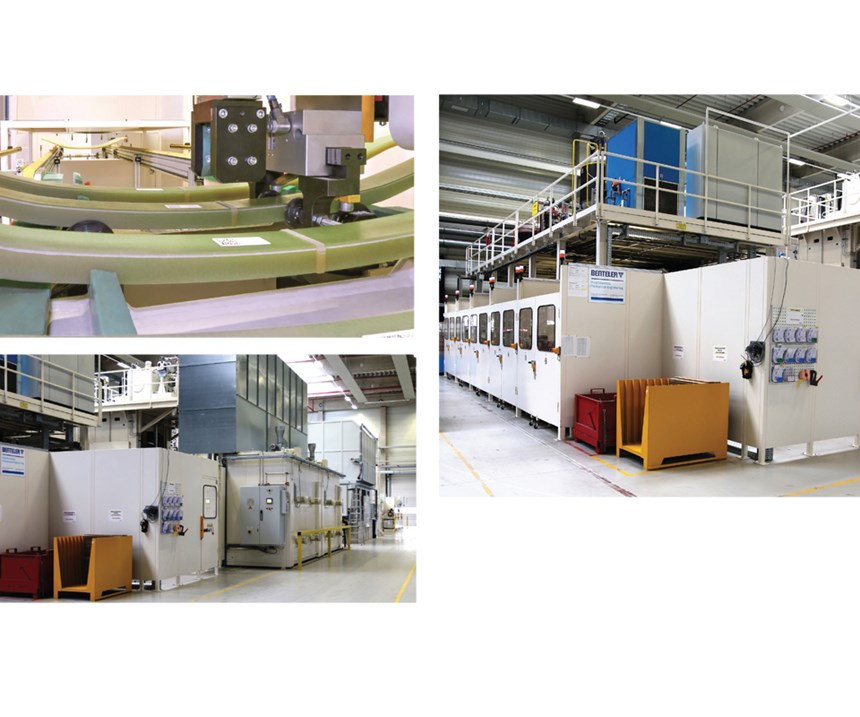

Standing in front of a production cell, Ascher explains, “The specific leaf spring being produced will change through the day per computer-controlled production management system. Everything is JIT [just in time].” Within the cell, an automated cutting machine, supplied by BENTELER Mechanical Engineering on the left, alternates between cutting rolls of unidirectional (UD) fabric and NCF. A robotic arm picks and places cut plies into a preforming station at right. A quality assurance (QA) kiosk sits across from the preform station. “If it detects an issue, it automatically fixes it,” says Ascher. “For example, if the material orientation or placement is not accurate, it will move the material.”

The tour walks north, passing on the right pits in the floor that are pre-wired and ready for new presses in anticipation of future growth. Turning left, the all-white, self-contained Volvo leaf spring line fills the west end of the building. Currently the world’s highest-volume autocomposites production line, it is a massive, industrial cell, arranged linearly from material input at the west, through cutting, preforming and RTM, to rows of machining cells at the east, followed by testing cells. “We bend-test every spring,” notes Ascher. Located midway along the length is a mass-capable oven for post-curing the leaf springs (Fig. 4). The process requires no manual steps, yet manages nine combinations of upper and lower tools and mates them with multiple machined hole configurations for spacers and bushings. As a result, it can output the appropriate leaf spring variants in response to an ever-changing mix of large and small vehicle orders (see 500,000 parts per year? No problem!).

Walking up onto a mezzanine where the resin storage, heating, metering and mixing equipment is arranged, the tour turns to face west. From that vantage point, it is clear there are actually two mirrored leaf spring production lines. Rolls of glass fiber UD fabric enter and are processed in dual automated cutting stations. In each line, a robotic arm transfers cut plies onto stacking tables and then moves completed stacks into a dual-cavity press where they are consolidated into leaf spring preforms. On the other side of the preform press, a second set of robotic arms transfers preforms into one RTM press for each line. These robots run on a linear track from the RTM press to multiple machining cells (Fig. 4). “Making a leaf spring out of composite is not rocket science,” says Ascher, “but how to set up this equipment and make these parts in a fully automated way with both lines integrated and running together, this is a challenge.”

All of the robotic arms are sourced through BENTELER, which also supplied a majority of the Volvo leaf spring line’s machinery. “We have our own division in BENTELER Automotive internal mechanical engineering, which builds our equipment in-house,” Ascher explains. “All of our process control software is developed internally as well.”

Only three technicians must be on the floor during production on this line, but others operate behind the scenes, monitoring system performance and re-engineering it, where necessary.

Structured for continuous improvement

Leaving leaf spring production, the tour stops by an enclosed control room, located mid-span on the north side of the hall, that functions as a “war room” for the whole plant. There, metrics are tracked for logistics and employment, and to support efforts for continuous improvement — keys to ensuring performance at the site, in production, maintenance and safety. “This is a daily management area to have the right focus and find quick solutions,” says Ernst-Seibert. “We plan ahead. This expertise comes from BENTELER Automotive.”

“This also serves to inform employees so they have a big picture and can see how to contribute to success,” adds Birgit Held, VP corporate communications/marketing for BENTELER International AG. “We also show and discuss ideas for improvement. It’s about people — those working at this site know its operations and issues best. We need to benefit from their ideas, so we provide a structural loop for this.” She says that employee ideas are awarded each year, and progress in addressing and implementing ideas is monitored. “For example, if it is taking too long for an idea to be answered, then it may go to the managing directors,” Held explains, noting that reaction and answering time should not be too long.

CFRP production

The tour resumes, entering the CFRP production area. To the left is an automated cutting station with a long table. Up to 10 layers of material can be cut simultaneously as required for parts in production — four to seven plies is normal. A robot pulls rolls of reinforcement from an inventory shelf along the north wall. Each roll is scanned into the digital enterprise resource planning (ERP) software, which tracks inventory and overall production, but also builds a digital “paper trail” for each part. There will be a barcode on the end of each part to log material and roll data.

The precut material stacks are placed onto a cart that is then rolled a few feet to a heated press, where they are consolidated into a preform. The parts in production during the tour were transferred in and out of the press manually, but Ascher notes, “If the volume is high enough, we automate.” Preforms are then fed into two HP-RTM presses.

The machine shop for equipment maintenance lies just beyond the CFRP production area, in the building’s northeast corner. Across the aisle from it is the wet pressing area (see Wet compression molding). “Under-floor parts for automotive are a good shape for wet pressing,” says Ascher. Like the Volvo leaf spring line, resin storage and mixing/dosing functions are situated on a mezzanine to conserve space and enlist the help of gravity to feed resin to the presses. The single-process cell comprises two wet pressing lines with integrated robots for automated transfers. The presses form the rectangular cell’s two rear corners. A dosing robot, its centerpoint, applies resin to preforms and transfers these to two tables, one for the leftward press and another for the press on the right. Two other robots, one in front of each press, transfer the wetout preforms from the tables into the presses and then back out after cure to finished-part trolleys. Every part in the wet pressing line is inspected — checked for flatness, dimension and shape — and then trimmed and machined.

CFRP machining and MSS assembly

BENTELER SGL’s machining area sits at the production hall’s east end. Its four CNC machining bays house two conventional milling machines and two waterjet systems.

The tour now turns back toward the west, where a long row of six production cells comes into view. These are used to assemble the Audi Modular Sportscar System (MSS) platform’s rear shelf and B-pillar as an integral reinforced sandwich component (Fig. 1).

This component is distinctive for several reasons: First, a planned common architecture for multiple Audi, Porsche and Lamborghini models, the MSS rear wall integrates 27 RTM parts made from 42 preforms, including left and right struts, four backplane components and two components each for left and right upper B-pillars. It’s used for the Lamborghini Huracan and Audi R8, and received a 2016 JEC Innovation Award for BENTELER SGL and teammates Audi (Ingolstadt, Germany) and Evonik (Essen, Germany). For this part alone, BENTELER SGL fabricates more than 311,000 preforms and 200,000 composite parts per year at Ort im Innkreis.

Second, the manufacturing process for the MSS composite elements — named ultra-RTM — includes developments in fiber forms, fast-cure resins and low-density foam cores with integrated fasteners. According to Audi, the combination of these technologies enables exploitation of differential construction for high-volume production, achieving the lightweight and performance of a monocoque without being restricted to long cycle times and, thus, small-series production. Reportedly, the main challenge is infiltrating the complex, foam-cored, insert-integrated parts with resin within a short processing window. The key is process control during resin injection via in-tool sensors, which BENTELER SGL has obviously mastered.

Third, it’s a showcase example of BENTELER SGL’s ability to manage the many facets of multi-material manufacturing. “This is the most complex part that we build right now,” Ascher notes. Indeed, production of the MSS module manages four derivatives, using 242 supplied components, many made from aluminum, and requires 17 bonded joints achieved through 146 adhesive operations. Part development began in 2009 and production commenced in 2013. “This part makes a difference vs. our competitors,” says Ascher. “We know how to integrate aluminum into the part’s structural function and how to automate complex assembly with bonded and mechanical fasteners. Both partners built extensive knowledge through this development.”

The CFRP parts are bonded with polyurethane, but bonded fasteners and mechanical fastening also are used in final assembly. Bins full of fasteners can be seen, positioned across from the automated assembly cells. In one of the cells, a robot is applying polyurethane adhesive. The cell’s automated door opens, a worker manipulates a metal bonding jig, closing its two wings and back section onto the main composite piece. The jig will hold and locate this piece while adhesive is applied, and subsequent pieces are located and held in place during adhesive cure. The assembly is built up in subsequent cells, with some including installation of fasteners.

Future materials, processes, and parts

Although epoxy and polyurethane dominate production at BENTELER SGL, thermoplastics are an option. “For us, there is no preference for thermoset or thermoplastic,” says Ascher. Ernst-Seibert adds, “We adjust ourselves to market needs and we can do this quickly. We’re not afraid of new materials or processes, but our focus is on structural and semi-structural parts. Thus, HP-RTM is an expertise. So we can produce structures with Class A finish but we can also use thermoplastic HP-RTM if necessary. The key point for us is the part and its design. We excel when the design and production is complex.”

This adaptability is also exemplified, Ascher notes, by another capability: “We have a fully automated wet pressing process installed here, delivering very short cycle times for low- to mid-complex geometry.” He notes it is a good process for thin-walled components, “but this is not the end of wet-pressing technology. Currently, it cannot handle undercuts, in which case we would go to RTM. But we are working to develop this capability in wet pressing.”

With regard to parts, Ascher sees continued growth in leaf springs and large, integrated structures for high-end vehicles and sports cars. Ascher says the biggest growth market is in China, “and they are willing to pay for the technology and to be a leader.” Although it offers significant opportunities, the US automotive market, Ascher says, remains cautious about composites. Regarding concern about a reliable supply chain, Ernst-Siebert notes that SGL’s carbon fiber production plant in Moses Lake, WA, US is not only for BMW, but open to supply other automotive OEMs and tier suppliers, as announced in 2016. BENTELER SGL also is ready to aid further development in the US or elsewhere. Says Ascher: “We can reduce the complexity for companies wanting to move forward with CFRP applications and apply proven technology in huge volumes, based on our significant experience and capabilities.”

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More