Aerospace

Topology optimization

For Airbus (Toulouse, France), topology optimization is just one of many computer-aided optimization techniques that have been employed in the aircraft design process — and employed ever earlier — to reduce time and cost.

Read MorePanelized option attested early on

Airbus' (Toulouse, France) use of large composite panels attached to frames in the A350 fuselage — is comparable to the optimal design conclusion reached by the Advanced Technology Composite Aircraft Structures (ATCAS) program back in the late 1990s.

Read MoreA350 XWB update: Smart manufacturing

Spirit AeroSystems actualizes Airbus’ intelligent design for the A350’s center fuselage and front wing spar in Kinston, N.C.

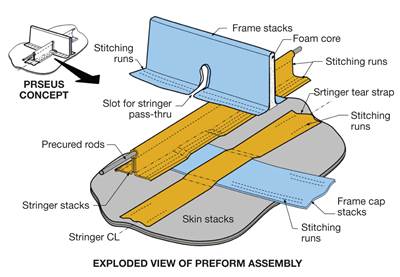

Read MorePRSEUS preform for pressurized cabin walls

Over the next few years, NASA and The Boeing Co. (Chicago, Ill.) will build larger and more elaborate pressurized passenger cabin structures for future blended-wing airliners.

Read MoreSoftware speeds tape layer production, optimizes precision

the Siemens Aerospace Center of Excellence's (Elk Grove Village, Ill.) developed the Siemens SINUMERIK 840D CNC system speeds production on a large ATL machine at the former Boeing Wichita plant (now Spirit AeroSystems) in Wichita, Kan.

Read MoreAn out-of-autoclave progress report

CW Conferences director Scott Stephenson recalls Dale Brosius’ update on Quickstep’s out-of-autoclave work for the F-35 program.

Read More2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

Read MoreComposites on the re-engined 737NE?

Jeff Sloan, editor-in-chief of High-Performance Composites magazine, comments on the impact of The Boeing Co.'s (Chicago, Ill.) decision to re-engine its fabled 737 single-aisle passenger jet. What remains to be seen, he says, are what composites opportunities there might be on the 737NE.

Read MoreTooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

Read More