Aerospace

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read MoreOld is new in vacuum bonding honeycomb sandwich

In Care and Repair of Advanced Composites (published by the Warrendale, Pa.-based Society of Automotive Engineers in 1997), Dr.

Read MoreGKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

Read MoreCFRP upgrades economy seating

First aircraft seat to use visible CFRP revolutionizes aesthetics and comfort.

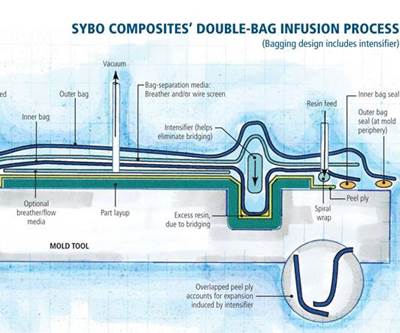

Read MoreDouble-bag infusion: Thickness gradient and pressure

Cliff Walker (Vacmobiles, Auckland, New Zealand), explains how the large pressure changes during infusion result in laminate compression and thickness variations across the part.

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreInternational Building Code: Meeting requirements for interior composites

How to produce FRP parts that can meet International Building Code flame-spread and smoke-obscuration specifications.

Read MoreUnmanned Systems North America 2010

Growing trade event underscores composites’ continuing vital role in unmanned systems for aviation and marine applications.

Read MoreShape shifters: The molecular basics

The key to SMP shape change is the fact that an SMP can exhibit a radical transformation from a rigid polymer to a malleable elastomer and back again.

Read More