Ceramic fiber AFP

3M’s dry fiber towpreg combines spread-tow, high-denier Nextel 610 alumina fiber with an alumina matrix that is room-temperature stable (no cold storage required) yet offers a layup time of days to weeks. Its performance is being proven in AFP with Electroimpact and selected customers for a variety of process and part trials including this exhaust cone structure. Photo credit: 3M

Ceramic matrix composites (CMC) use ceramic fibers to reinforce a ceramic matrix, improving fracture toughness while maintaining high-temperature (>1,000°C) performance. They operate in temperatures up to 400°C higher than nickel super alloys with a fraction of the density. This combination enables metals replacement and efficiency improvements in applications such as aerospace engines, supersonic and hypersonic aircraft, space vehicles, heat exchangers and industrial gas turbines.

Recognizing the importance of these benefits, GE Aviation (Evendale, Ohio, U.S.) established its own supply chain for the manufacture of silicon carbide fiber-reinforced silicon carbide (SiC-SiC) composite parts for its engines. It has also invested in Ox-Ox CMCs using aluminum oxide-based (alumina, Al2O3) fiber and matrix, including the mixer for its long-range business jet engine, the Passport. Though the temperature resistance of Ox-Ox composites is not quite as high as SiC-SiC (1,100°C vs. 1,600°C), the manufacturing cost is much lower, and the material properties are well suited for engine exhaust components and heat shields.

3M (St. Paul, Minn., U.S.) Nextel 610 and Nextel 720 alumina-based fibers have been used in high-temperature applications for decades. “Traditionally, the industry has used 1500 denier rovings woven into an 8-harness satin fabric,” notes Tim Shumate, vice president of sales and marketing for Composites Horizons Inc. (Covina, Calif. U.S.), which makes the Ox-Ox mixer for the Passport engine. “That fabric gets coated with a slurry to form an Ox-Ox prepreg, which is then made into parts using hand layup,” he adds. “High material cost and high part cost has been an impediment to wider adoption.”

3M has been working with Composites Horizons Inc. and other customers to evaluate the use of higher-denier rovings to provide lower-cost options. “It’s analogous to how larger-tow carbon fiber results in lower material cost per pound,” Shumate explains. “We’ve demonstrated that 3000 and 4500 denier rovings can produce fabric prepregs and parts that are equivalent to using 1500 denier materials. And then 3M wanted to use even higher deniers, up to 10,000.” The resulting fabric was too coarse, but 3M had already been working on spread tow and how Nextel fiber might be made into tapes.

“Our goal is to enable our customers to expand both Nextel fibers and Ox-Ox CMCs usage beyond where they are used today, including price-sensitive commercial engines and industrial applications,” says Clara Choe, 3M business development lead for Nextel ceramic fibers. “We see real benefits in using high-denier fibers combined with low-waste and high-throughput automated manufacturing. We wanted to develop a drop-in solution for the automated fiber placement (AFP) equipment that composites manufacturers are already using to produce carbon fiber-reinforced polymer (CFRP) materials.”

Spread-tow Nextel towpreg

“One of the enablers for towpreg is spread tow,” explains 3M towpreg project leader Aaron Beaber. “We developed this technology in the past two to three years and are now working on the next generation of products. This technology is unique to Nextel ceramic fiber, which is more sensitive to shear damage versus carbon fiber. We have a proprietary method that applies enough shear to open up the fiber without damaging it.”

The next development needed was a matrix that was amenable to AFP processing. “Normally, if you touch an Ox-Ox prepreg, you get a white grit of aluminum oxide particles on your fingers,” Shumate notes, with the implication being that such particles can be problematic to an AFP machine.

Beaber adds: “We knew we needed a prepreg that would not gum up the AFP machine, yet would have sufficient tack for adhering during placement. We had to develop this solution from scratch. We also wanted to use a water-based product for environmental, health and safety reasons. However, we struggled with stability during manufacture. Finally, we found the right formula, producing a room temperature-stable prepreg tape. We call it a dry towpreg because it is less than 5% water by weight.”

The Nextel 610 towpreg also has minimal tack until it is heated above 100°F. “It’s more like a thermoplastic prepreg which gets heated in the AFP head and then sticks as you lay it,” Shumate says. Similarly, the material does not require cold storage. “The key with epoxy prepregs is that the matrix system is pretty reactive, so you typically store them cold to prevent any chemical reaction before layup and cure,” explains Amit Patel from 3M’s corporate research lab supporting this product. “We wanted to avoid this. However, the chemistry for a ceramic matrix is also very different from epoxy in that the organic part of the matrix is basically removed during the high-temperature processing to create the CMC. That gave us flexibility to go a different route.”

Unlike thermoplastic prepreg tapes and towpreg, in which the AFP head uses laser heating, the Nextel 610 towpreg was developed first for infrared (IR) heating. “IR is the most prevalent, and already used with epoxy prepreg,” says Beaber. “It’s also easier to run, not requiring laser safety interventions. But we can see the industry is increasingly using laser heating, so we are investigating that now.”

Fig. 1. AFP performance

Nextel towpreg (white) on a polyethylene liner (red) has proven its performance in trials on an Electroimpact AFP machine, achieving fiber steering down to a radius of 1,000 millimeters onto bare PET, matching or even outperforming traditional CFRP towpregs. Photo credit: 3M

AFP success

3M worked with AFP systems supplier Electroimpact (Mukilteo, Wash., U.S.) to run processing trials. “This towpreg is much stiffer and more brittle than most carbon fiber towpreg,” Beaber notes. “We were hesitant about the fiber path within the AFP head, knowing the tight turns it must make and tensioning. We thought the Nextel fiber wouldn’t survive, but it worked fine.”

“From an AFP equipment and process point of view, nothing is preventing our equipment from making large parts with the Nextel 610 towpreg,” says Andrew Purvis, composites automation project manager for Electroimpact. “The material processes at about 800-1000 inches/minute, which is about the same as for BMI (bismaleimide) materials.” Initial processing and speed trials were conducted on six-inch by six-inch test panels. “We could easily program and layup much larger, more complicated parts,” Purvis adds.

“We’ve made more than 80 test panels over the past year,” says Beaber, “including 0°/90° layups that were then consolidated, sintered and tested for mechanical properties.” So far, properties are in the same range as fabric-based Ox-Ox composites. “Our initial goal wasn’t to exceed fabric-based CMCs, which rely heavily on hand layup, but to match that performance using automated layup,” Patel explains. “We are also looking at how we can improve that performance.” For example, samples to date show a little over 40% fiber volume, which is typical for CMC, but lower than the 60% fiber volume typical for CFRP. “We’re looking at how much we can dial that up and down versus how the material then processes in AFP and the resulting CMC mechanical properties.”

Another difference is that this towpreg is not slit. “When spread, our 10,000 denier fiber ends up being a nominal 0.25 inch wide, and our 20,000 denier fiber spreads to a 0.5-inch width,” says Beaber. “These are the sweet spot for conventional AFP, chosen for throughput but also for resolution. We are focusing first on the 0.25-inch width.”

He explains that while the thickness tolerance for the Nextel towpreg is quite tight, similar to CFRP towpreg, “the width tolerance is different because we’re not slitting. Width tolerance for CFRP towpreg is ±5mils, but for us it is ±50 mils. Slitting would reduce the tolerance, but it would also increase the cost. We initially got pushback from our customers on this, but after trials we’ve found we’re able to match properties versus conventional fabric laminate CMC, even with this 50-mil tolerance. So, a tighter tolerance may not be needed, especially if it would greatly increase cost. The wider window is a difference but not a barrier to getting the properties needed.”

Fig. 2. Fabric vs. towpreg parts

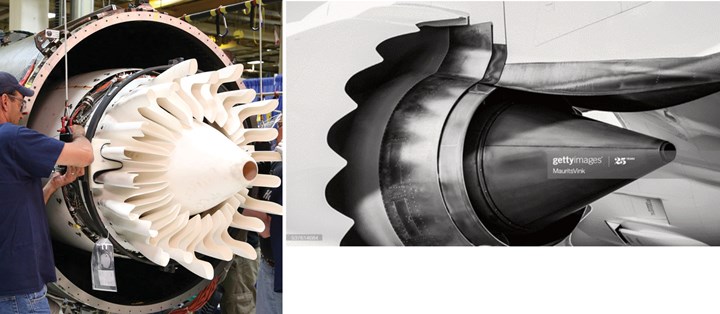

Nextel fabric-based prepreg will still be required for complex-geometry parts like the Passport engine mixer (left) while Nextel towpreg is aimed at less complex shapes including engine exhaust cones, nacelles, pylons and other structures where required temperature resistance is increasing as engines get hotter (right). Photo credit: GE Aviation (left), Getty Images (right)

Proving out performance

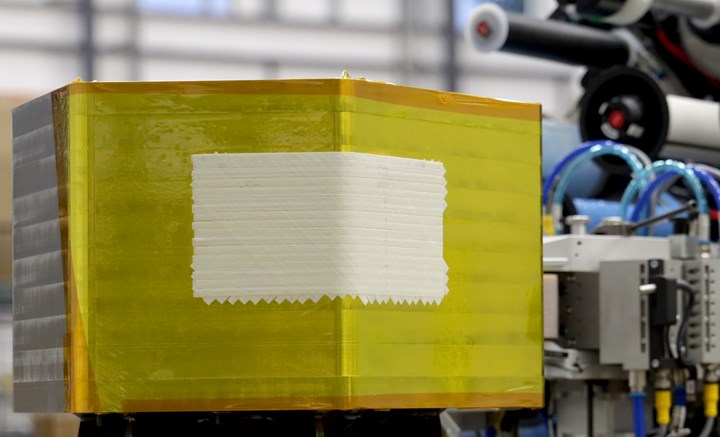

3M is also working with Electroimpact, Composites Horizons Inc. and other customers to prove out the Nextel towpreg’s performance in representative parts, such as the exhaust cone structure in the opening image and the angled tool in Fig. 3. “We needed to demonstrate where this technology works well and where it starts to fail,” says Beaber. “Thus, we created a tool not representing any real part, but instead integrating five different features from aerospace parts — such as certain angles and radiuses — enabling us to complete trials without changing tools all the time.”

Fiber steering was also evaluated. “We had to develop a new adhesive package in order to test this because our fiber stiffness is higher than most carbon fibers,” Beaber explains. “Also, there is no standardized test for this. So, we had to develop something on the fly. We bracketed the performance by using a carbon fiber towpreg as a high-tack substrate and compared that to trials on a PET [polyethylene terephthalate] thermoplastic to simulate the worst case of no tack. Using 0.25-inch-wide Nextel towpreg, we were able to AFP onto the PET down to a radius of 1,000 millimeters without defects. We’re in the ballpark, if not better than, traditional carbon fiber towpregs.”

That’s not to say the ceramic fiber towpreg is without certain challenges. “The material is abrasive,” Beaber concedes. “So, you could basically polish the roller as you run this material and potentially transfer metal flakes into the part.” A potential solution is a wear-resistant coating for the rollers, such as aluminum titanium nitride (AlTiN), which has shown good initial results.

Electroimpact sees two areas that need additional consideration. “Because the material does have some build-up in the head, you need to have the correct equipment-cleaning regimen,” Purvis says, “and the surface of the molding tool requires the appropriate surface preparation for generating the right amount of tack.”

Fig. 3. Proving part features

This angled tool integrates five features from aerospace parts, enabling multiple AFP trials without changing tools. The yellow Kapton polyimide film is not necessary for AFP processing of Nextel 610 towpreg, but is required for release after the high-temperature autoclave sintering which converts the layups into a green CMC body. Photo credit: 3M

Commercialization timeline

“We’re sampling now to a select number of customers who have significant experience with Ox-Ox composites production and AFP,” Choe says. “We are looking at our product and making sure it can meet their specifications. Full commercial availability is a couple of years out, but we’re scaling at the same time, so we will be ready. For now, we are releasing general properties, but we will refine these and publish full data sheets as we move through qualification with our customers.”

“Using AFP for the production of CMC parts is the natural progression,” says Purvis. “We would like to see more CMC material forms that can take advantage of digital and additive processes such as AFP and 3D printing (see “Combining AFP with 3D printing for flexible parts production”). With the Nextel towpreg, you are leveraging the most productive, flexible, fully developed automated manufacturing technology for making high-performance composite parts, just optimized for a new material system. This should allow for the design and manufacture of higher performance parts with a lower scrap rate versus hand layup and less material needed because UD tow allows for lighter and stronger parts.”

“The real benefit of this technology is the potential to yield a low-cost material to create a low part cost,” says Shumate. “AFP becomes economical for large parts at Boeing due to the amount of material laid down. But no one wants to make 40-foot parts using CMCs. We’re talking about parts that are maybe 1-foot by 1-foot or a 6-foot by 3-foot duct. The value proposition for us is in using the higher-denier fiber to greatly reduce oxide CMC prepreg cost.” Conventional Ox-Ox fabric prepreg can account for as much as 70-80% of the final part cost.

Shumate notes that towpreg won’t be for all parts. For example, complex shapes like a mixer require the conformability of a fabric. “But for less complex contours, there is a lot of potential. And potential also for achieving higher repeatability in parts via the automation of AFP. 3M has done a great job to make a material that runs well without having to significantly alter the AFP equipment. Now, it’s just a matter of proving out the laydown rate with contoured parts, dialing in the CMC processing and finalizing the cost.”

What will the cost be? “We are validating our cost model,” says Choe. “We know for some applications the price points of low-denier fabric are too high. We recently launched a higher-denier fabric to enable more competitive solutions for our customers. But low-cost towpreg with low-waste and high-throughput AFP processes can challenge the cost of a lot of titanium and Inconel parts.”

Related Content

ORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

Read MoreGeneral Atomics wins DOE contract to develop silicon carbide CMC for fusion power plants

GA-EMS will leverage experience with SiGA SiC/SiC cladding for nuclear fuel rods to develop new SiC composite foam and other materials for fission and magnetic fusion programs.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreBombardier begins manufacture of Global 8000 business jet

Ultra-long range business jet featuring CMC-intensive engine and a range of 8,000 nautical miles is set to enter service in second half of 2025 as it remains on track for flight testing.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More