ATL/AFP

Toray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

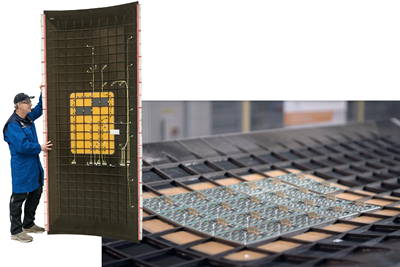

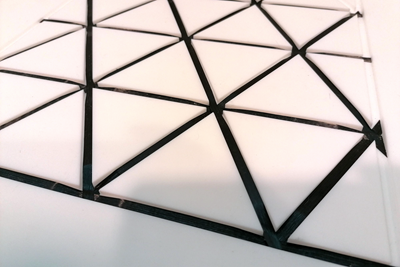

Read MoreIntegrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

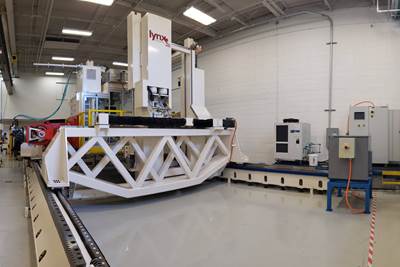

WatchUT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

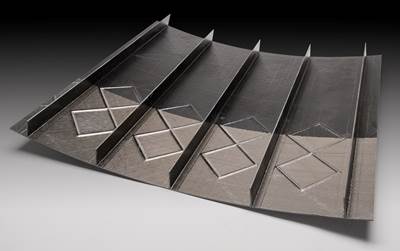

Read MoreSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

WatchMcNAIR Aerospace Center installs Heraeus Noblelight humm3 technology

Composites heating technology will comprise of a fully integrated system with a plug-and-play head module to further extend AFP and cylinder production capabilities.

Read MoreRocket engine thrust frame proves a strong candidate for composites conversion

The engine thrust frame of a space launch vehicle, located at the bottom of a rocket stage, joining fuel tanks to engines, must deliver strength and stiffness across a range of temperatures — cost-effectively.

Read MoreAxiom Materials announces narrow slit tow prepregs for electric, CNG and hydrogen-powered vehicles

High-temperature carbon fiber tow prepregs are compatible with AFP and filament winding processes for the development of large structural parts such as lithium-ion battery containers or pressure vessels.

Read MoreElectroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

WatchEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

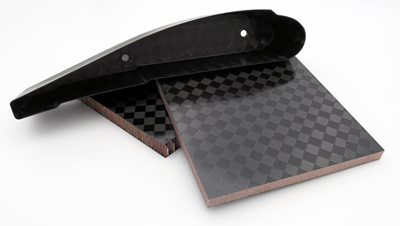

ListenDevelopment of composite isogrid structures using innovative deposition technology

Versatile robotic system integrates in-line towpreg impregnation, offering reduced-cost, high-performance isogrid structures for a variety of industries.

Read More