ATL/AFP

Quebec composites development center installs AFP capability

Robotic cell by Effman, Fanuc and Addcomposites enables automation of complex composite layups with tailored fiber orientation for small and medium enterprises (SMEs).

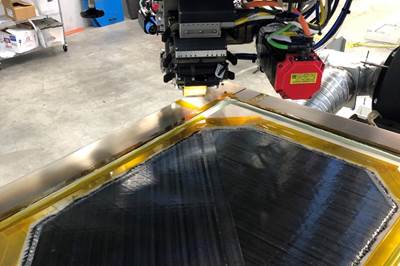

Read MoreThermoplastic tapes continue to show potential for composite aerostructures

Web Industries reports increased R&D activity within several aerospace markets enabled by the flexibility and advantages of thermoplastic tapes.

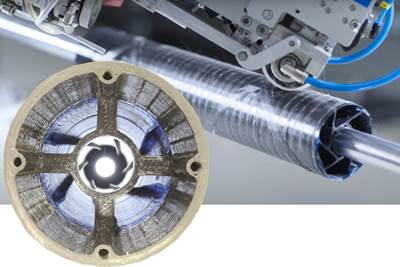

Read MoreElectroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

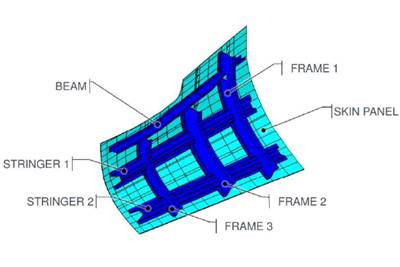

Read MoreClean Sky 2 FRAMES project advances heating simulation of thermoplastic composite AFP with xenon flashlamp

Heraeus Noblelight and Compositadour develop heating simulation to optimize process temperatures during automated fiber placement of composite aerostructures.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreCAMX 2021 exhibit preview: University of Dayton, ZSK

The University of Dayton Research Institute and ZSK Embroidery Machines’ collaborative booth showcases the latest developments in tailored fiber placement equipment and technology.

Read MoreCAMX 2021 exhibit preview: Gascogne Flexible

Gascogne Flexible showcases a tight release valve for ATL applications, a low coefficient of friction, solvent-free release liner and a high-porosity kraft paper for thin ply prepreg applications.

Read MoreCAMX 2021 exhibit preview: Helicoid

Designed for toughness and impact resistance, Helicoid Industries’ biomimetic fiber distribution technology, Helicoid, enhances performance of composite parts.

Read MoreCAMX 2021 exhibit preview: Carbon Axis

Carbon Axis showcases compact AFP solutions for the preforming of small parts with the XCell, XPlace mk2 and IdeaLab.

Read MoreThe evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

Read More

.jpg;maxWidth=300;quality=90)