Autoclave

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read MoreNew filament to make composites "smart"

CW Conferences director Scott Stephenson premiers a showcase for new ideas overheard at CW Conferences.

Read MoreGKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

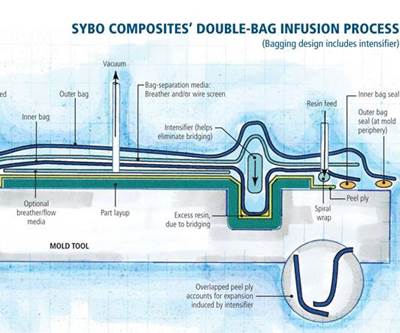

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

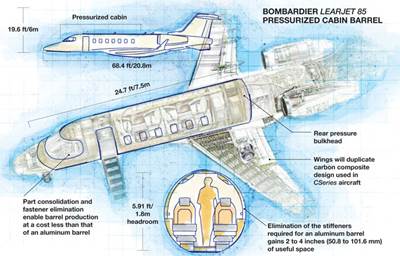

Read MoreLearjet 85 composite pressurized cabin a cost cutter

Single-piece carbon fiber composite structure selected over multipiece aluminum fuselage barrel section in new bizjet design.

Read MoreHigh-Performance Resins 2010 Highlights

Inaugural conference for the advanced resins research crowd updates formulators and processors on the latest developments.

Read MoreMedical applications: A healthy market

Composites make advances in devices for medical diagnosis and treatments that promote healing and help return patients to active lives.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

Read More

.jpg;maxWidth=300;quality=90)