Automotive

Automotive composites: Structural underbody

For Detroit’s Big Three, a joint precompetitive composite design, development, fabrication and testing program nears successful completion.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

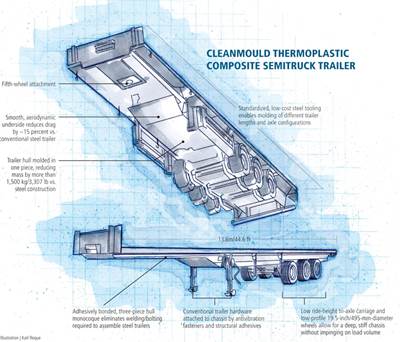

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read MoreUnder the hood: Thermoplastics tackle tough jobs

Reinforced plastics save weight and cost, increase underhood productivity.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreDrag racing champ wins with composite rear wing

A composite rear wing assembly built by Aerodine Composites Group (Indianapolis, Ind.) was critical to 2010 NHRA Full Throttle Drag Racing Series champion Larry Dixon’s effort at the wheel of the Al-Anabi Top Fuel dragster.

Read MoreLife Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

Read MoreQ&A Forum: Automotive Composites

How will fiber-reinforced polymers fare in a post-recession, cost- and fuel-economy-obsessed auto market?

Read MoreFuel cells (finally) set to power composites growth

Fuel cells and related technologies will form a sizable new market as they move past the phase of demonstration projects, overcome longstanding technology hurdles and gain momentum in their progress toward affordability.

Read MoreSPE's ACCE 2010 Highlights

The Society of Plastics Engineers’ Automotive Composites Conference & Exhibition completed its first decade with a stellar slate of keynotes and papers.

Read More

.jpg;maxWidth=300;quality=90)