Composites 4.0

Artemis Technologies and Creative Composites partner on eFoiler to cut drag on fast vessels by 90%

Composites-intensive electric propulsion system will make marine travel at high-speed and long-range commercially viable and help meet U.K.’s 2025 zero-emissions requirements.

WatchAutomation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

Read MoreProving out LM PAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test Toray LM PAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

WatchJEC World 2020 preview: Aligned Vision

Aligned Vision is demonstrating how its BUILDGUIDE process control suite advances the digital factory with paperless layup and non-layup guidance, plus automatic inspection and documentation.

Read MoreInstitute for Plastics Processing at RWTH Aachen University to build "Smart Factory"

The Plastics Innovation Centre 4.0 is expected to open by 2022, and will be a completely interconnected, 4,205-square-meter R&D environment.

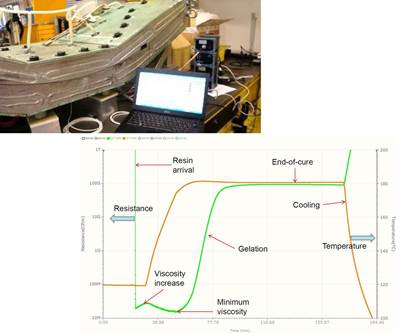

Read MoreDC dielectric sensors for industrial composites production

Synthesites in situ process monitoring enables cure decisions based on real-time Tg evaluation that can reduce cure cycles by up to 50%.

Read MoreCompression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

Read MoreCFRP preform technology is fast, flexible, efficient

Porsche racecar is first to sport part-via-preform technology.

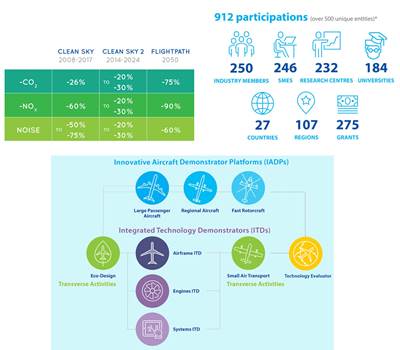

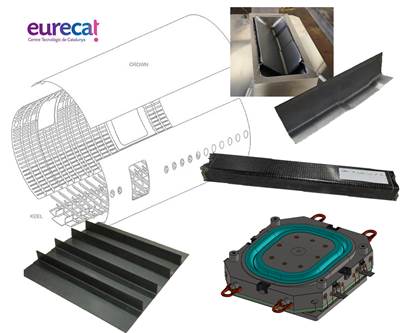

Read MoreAdvancing thermoplastic composites and RTM for Clean Sky 2 in Spain

EURECAT leads projects for TPC keel beam, window frames and thermoset RTM fuselage frames with TPC shear ties for next-gen aircraft.

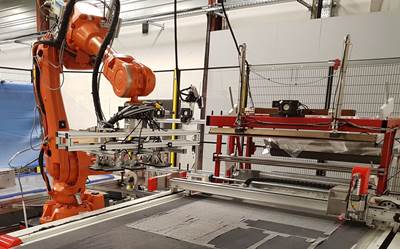

Read MorePlug-and-produce AFP system installed in one day and debuts at composites automation center

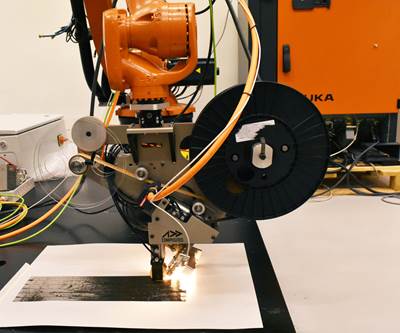

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

Watch