Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

Share

Read Next

Addcomposites (Helsinki, Finland) is revolutionizing automated fiber placement for composites production. Traditionally, when someone in the composites industry thinks about AFP and automated tape laying (ATL) systems, they immediately think of large, heavy robots laying up fiber for aircraft wings and fuselages, which require months of infrastructure upgrades, months to manufacture and integrate the system, and then another 6-8 weeks for actual installation at the customer's site. When the system does arrive, it comes in a vehicle-sized container and needs special equipment and operators to maneuver and install it. And it is a permanent installation.

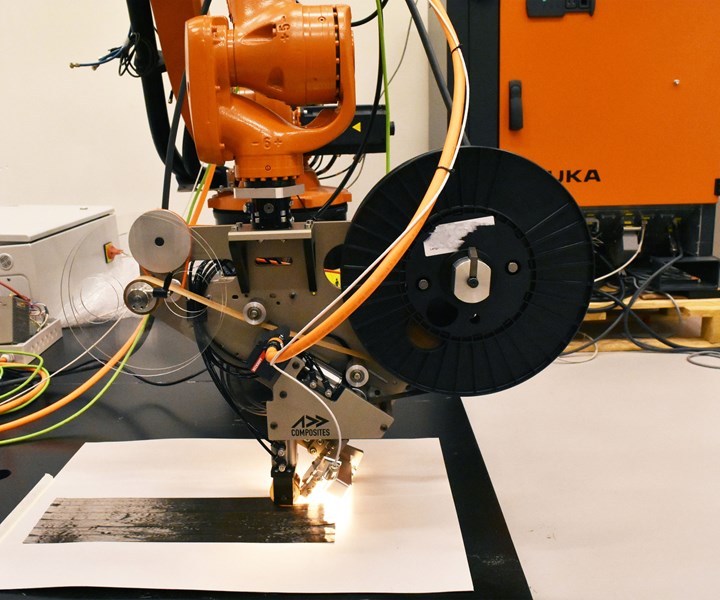

In mid-December (Week 50, 2019), Addcomposites did what was previously unheard of for AFP/ATL systems: loaded its AFP-XS toolhead and control box into the trunk of a car and drove two hours for an installation at KUKA Finland. The process began at 10:30, and by lunchtime, the system was installed and the base was calibrated. After lunch, multiple test layups were performed to ensure high-quality composites production. Once the quality was proven, everything was uninstalled and packed back up in the car, with the team on the road back to Helsinki before 16:30. “This is how easy it can be to do a demonstration, a short materials trial or a specialty production run,” says Addcomposites CEO Pravin Luthada.

“The plug-and-produce methodology has finally come to tape laying systems,” Luthada adds. “This is only one of the ways that Addcomposites is challenging the "traditional" norm of AFP/ATL systems.”

A full article with technical details of the installation and layup quality will be published in the Addcomposites Library.

AFP-XS installation at SAM|XL

Addcomposites completed its first customer installation of the AFP-XS toolhead at SAM|XL, a partner facility in Delft, Netherlands. SAM|XL is a collaborative research center specializing in automation for manufacturing large, lightweight composite structures in aircraft, wind turbine blades, spacecraft and maritime applications. It brings together TU Delft’s Aerospace Engineering group and Robotics Institute, as well as the Industry division of TNO, a Dutch innovation and research organization. Its consortium members include Airbus, GKN Fokker, KVE Composites Group, Airborne, Suzlon, CEAD, Curve Works, ABB, Fanuc, Hexagon Maufacturing Intelligence and many others.

“Addcomposites has successfully and efficiently integrated their tool into an existing robot cell with a complex layout, and with much legacy equipment already integrated,” said Rik Tonnaer, SAM|XL team member and automated composites researcher, TU Delft Faculty of Aerospace Engineering. “We look forward to working together with Addcomposites, continuously sharing knowledge and upgrading the AFP systems at TU Delft.”

Related Content

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.