Compression Molding

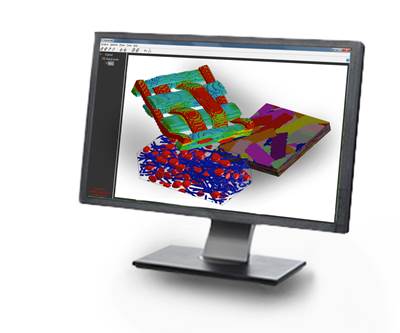

New Digimat 2019.1 release enables smarter fiber-reinforced composite design values, allowables and crash modeling

Upgrades include high fiber content virtual test with 10-100 times faster analyses and progressive damage analysis using the Camanho method.

Read MoreCorebon expands induction-based composites production into new facility

Results for cutting CFRP cycle time to be presented at Carbon Fiber 2019 conference.

WatchAdditive Molding promises mass-produced high-performance composites

Arris Composites introduces a patent-pending technology that manufactures high-performance thermoplastic composite components with a combination of additive manufacturing technology and high-speed compression molding. Has mass production of advanced composite components finally arrived?

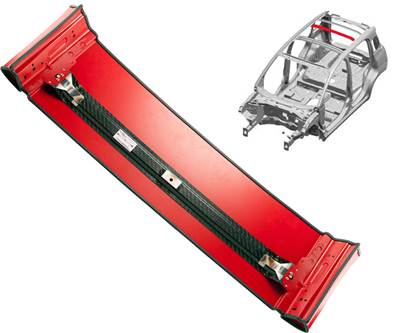

Read MoreKordsa works with Ford Otosan to develop composite leaf springs for heavy trucks

Prepreg compression molding prototype achieves 75% weight savings while boosting performance.

Read MoreSix candidates nominated for "Biocomposite of the Year 2019"

Natural fiber composites and wood plastic composites compete for 7th annual innovation award.

Read MoreComposites One to present advanced composites workshop

In partnership with the Closed Mold Alliance and IACMI, Composites One will present an advanced composites workshop on Nov. 6 in Clearfield, Utah, U.S.

Read More2019 CAMX award, ACE winners illustrate industry trends

Among this year’s award winners are Continental Structural Plastics, the Institut fur Textiltecnik of RWTH Aachen University, LyondellBasell, Fortify, Spirit AeroSystems and more.

Read MoreAutomated joining of hybrid metal-thermoplastic composite structures

The FlexHyJoin production cell combines surface structuring, induction and laser joining and NDT for automotive mass production.

Read MoreThermoplastics in the quest for aerospace weight savings

Safran Cabin, Victrex and Tri-Mack Plastics collaborate to migrate an aerospace storage bin from aluminum to an overmolded thermoplastic composite. The result proves the promise of thermoplastics in aerospace interiors.

Read MoreCompression presses keep evolving in response to composites innovation

Shorter, lighter, smaller footprint Fiberpress machines are ideal for facilities with lower ceilings, automated production lines.

Read More