Share

Read Next

Enabling industrial-scale hybrid joining

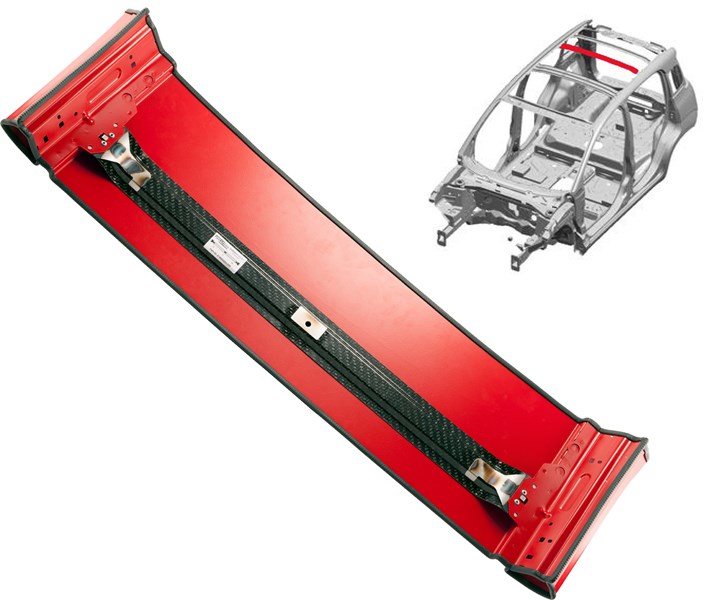

FlexHyJoin demonstrates a mass production process for producing a thermoplastic composite roof stiffener with welded metal brackets for assembly into a metal body-in-white, like that of the project’s use case, the Fiat Panda city car. Source | IVW

Hybrid metal-composite structures continue to be of interest for automotive and aerospace applications, offering reduced weight and improved performance by putting “the right material in the right place.” Thermoplastic composites (TPCs) are attractive for such multi-material structures due to their rapid processing, including the ability to be welded and thermoformed. However, joining composites to metals has, until now, relied mostly on mechanical fasteners, which require drilling holes that damage load-bearing fibers. Adhesive bonding has also been used, but a number of thermoplastics are difficult to bond in this way; also, adhesives add material and weight. For example, the BMW i3, which uses a carbon fiber-reinforced plastic (CFRP) chassis and plastic body panels, uses 16 kilograms of adhesive, which partially counteracts the weight-saving potential of composites.

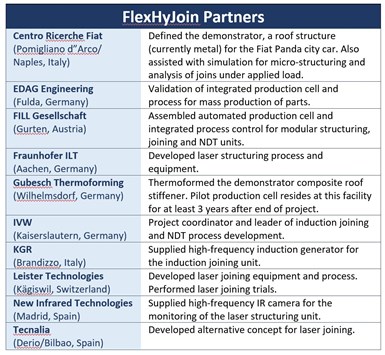

FlexHyJoin is a project funded by the European Union’s Horizon 2020 research and innovation program, conducted from Oct 2015 to Dec 2018, which sought to address the challenges of joining TPC and metal parts. Coordinated by the Institut für Verbundwerkstoffe (IVW) — a non-profit research institution of the state of Rhineland-Palatinate and the Technical University of Kaiserslautern, Germany — FlexHyJoin brought together 10 partners from across Europe to develop an automated process enabling a TPC automotive roof structure to be assembled into a metal body-in-white (BIW). The strategy was to produce a weight-neutral, high-strength join — without adhesives or fasteners — by laser pretreating metal brackets and attaching these to the roof stiffener via induction and laser joining. This was achieved in a single, automated production cell with integrated process control and inline nondestructive testing (NDT).

Hybrid demonstrator in 140 seconds

Project partner Centro Ricerche Fiat (Pomigliano d’Arco/Naples, Italy) supplied specifications for the demonstrator part — a roof stiffener for the Fiat Panda city car that is currently fabricated from steel. For FlexHyJoin, the part was thermoformed from thermoplastic composite (Fig. 1) by Gubesch Thermoforming (Wilhelmsdorf, Germany) using 1.5-millimeter-thick Tepex Dynalite 102 woven glass fiber/polyamide 6 (PA6) organosheet supplied by Bond-Laminates (Brilon, Germany). In order to join this TPC roof stiffener into the Panda’s steel BIW, a set of side brackets (left and right) made from 0.7-millimeter-thick DC04 steel were laser joined onto the ends. A center bracket made from the same material was attached using induction joining. FlexHyJoin showed that both joining methods can be used for industrial hybrid structures production.

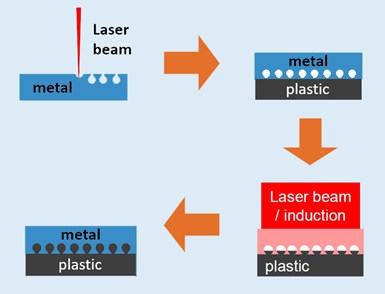

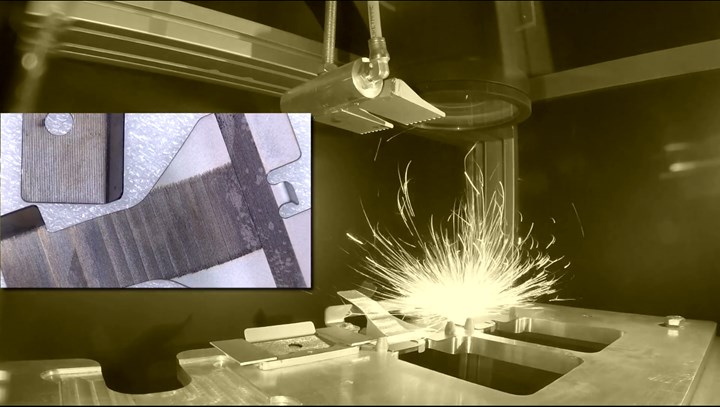

Fig. 1 Surface structuring for hybrid joining

FlexHyJoin demonstrates laser and induction joining of steel brackets to a stamped GF/PA6 roof stiffener (top). These hybrid joints rely on surface treating the metal brackets to create undercuts, which are filled with melted plastic during the joining process steps (bottom).

Source | IVW

Simply melting the PA6 matrix onto the steel brackets would not produce a join with enough strength to meet structural requirements. Thus, a laser surface treatment was required prior to joining. “The surface of the brackets was structured by a laser to create undercuts,” explains Johannes Voithofer, project manager at Fill Gesellschaft (Gurten, Austria), which was tasked with assembling and integrating the automated production cell. “The treated brackets are placed onto the composite part. Heat and pressure are then applied during joining, causing the PA6 matrix from the composite to flow into the laser-induced undercuts [see Fig. 1].” The structuring process was developed by yet another partner, Fraunhofer Institute for Laser Technology (ILT, Aachen, Germany), and results in a metal-composite join that combines material adhesion as well as mechanical locking.

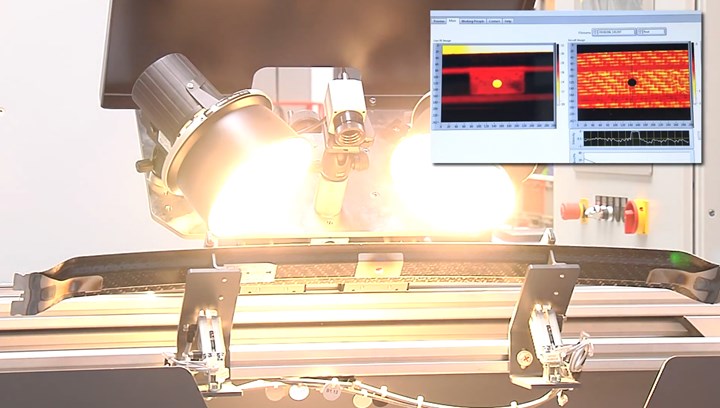

Joined parts are then transferred to an NDT station where they are scanned for defects using a type of thermography. “Halogen spotlights are used for modulated heating of the composite surface,” explains Vitalij Popow, IVW research associate and lead for developing the FlexHyJoin NDT and process control. “This leads to an oscillating temperature field within the composite structure. We analyze the thermal response on the surface over time and identify defects in the joints.” The fully automated testing is completed within the production cell for each manufactured component. The validation of the process was performed on about 400 joints.

The FlexHyJoin automated production cell, as currently configured, runs laser structuring, joining and NDT in parallel with cycle times of 81 seconds, 98-108 seconds and 100 seconds, respectively, not including time for robotic transfer of parts between stations. Voithofer says cycle time per completed hybrid part is roughly 140 seconds.

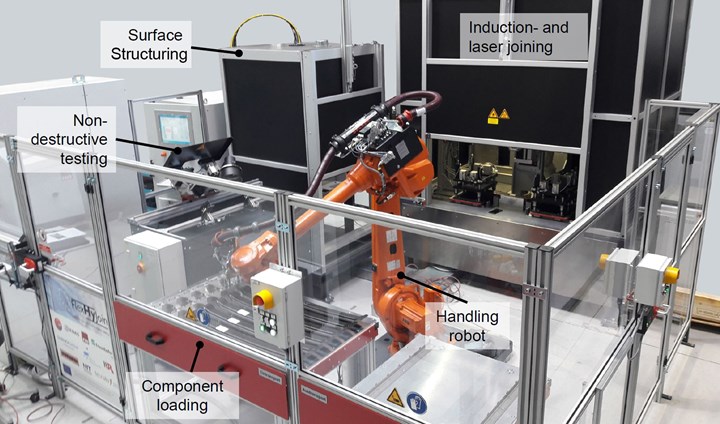

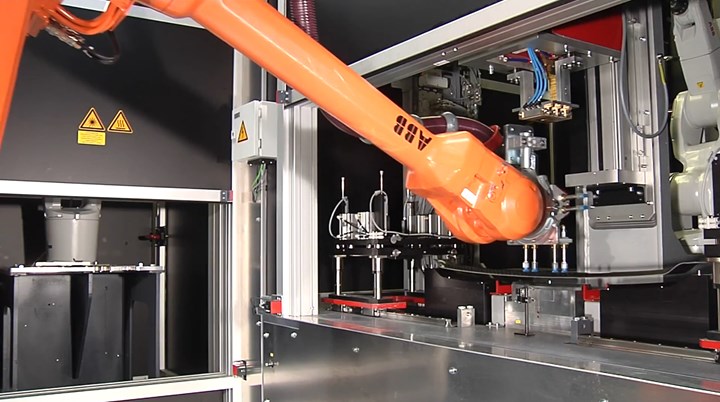

Fig. 2 Enabling industrial-scale hybrid joining

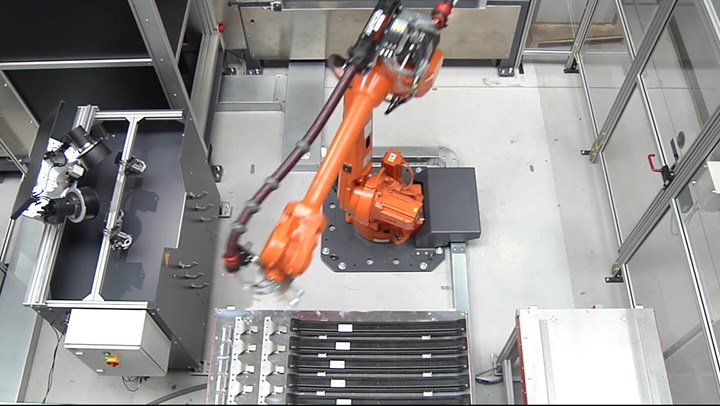

The FlexHyJoin pilot production cell features three modular stations for surface structuring, joining and NDT. The cell’s single handling robot transfers components from the loading drawer to each of these stations, placing finished hybrid parts in an adjoining drawer. Source | IVW and Fill

Laser structuring

The laser structuring process produces lines with undercut geometries on the joining surface of the metal brackets. For FlexHyJoin, the undercuts measured 75 micrometers wide and 215 micrometers in depth. These measurements, as well as the number of lines and overall pattern of lines can all be tailored, and, ideally, are matched to meet part and cycle time requirements.

“The position as well as the number of microstructures on the joining surface can be adapted to the loading in the component,” explains Stefan Weidmann, IVW research associate and leader of the development team for the FlexHyJoin induction joining unit. “The distance between microstructures can be reduced in highly loaded areas of the joining surface and increased in less loaded areas to enable an efficient microstructuring process.”

Structuring is achieved by ablating the metal bracket surface using a high-power, single-mode fiber laser supplied by IPG Photonics (Burbach, Germany). This YLR-1000-WC laser has a maximum output of 1,000 watts at an emission wavelength of 1,070 nanometers. “We used the single-mode fiber laser for the microstructuring process because of its high focusability, maintaining a spot size of roughly 40 micrometers,” explains Christoph Engelmann, team leader of polymer processing at Fraunhofer ILT.

The laser is contained within an optical head mounted onto an ABB 1200 robotic arm. “Inside the optical head, we have two galvanometric mirrors to deflect the beam in a 240-millimeter by 240-millimeter working field,” Engelmann details. “Furthermore, there is one movable lens to track the z-height (z-shifter). We only used the robot to position the scan head above the metal components, and then the beam is deflected by the mirrors and the z-position for each single line of the microstructure is adapted by the z-shifter. Thus, there is no movement of the head during processing. In this way, we are able to treat 2.5D parts, staying in the same z-position for each discrete line but able to adjust between lines.”

“For safety reasons, both the structuring and joining units are enclosed,” explains Voithofer, noting the black cabinets in the pilot production cell (Fig. 2). Thus, an automated gate/door remains lowered during laser operations, opening for removal of finished parts and insertion of new ones.

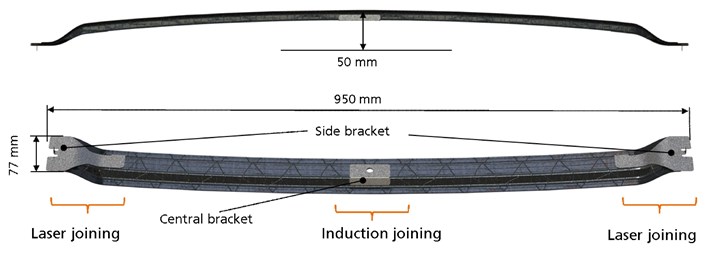

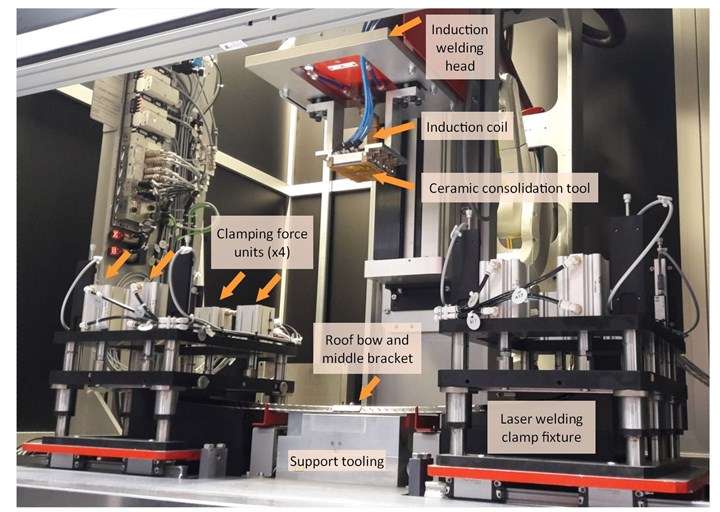

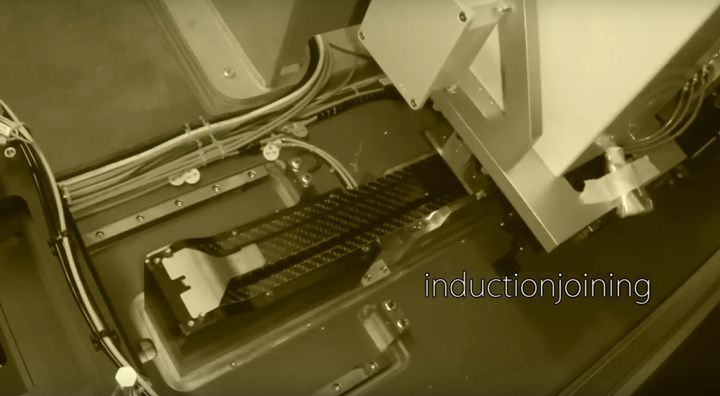

Fig. 3 Induction and laser joining cell

In the joining cell, induction joining is used to attach the middle bracket while laser joining is used to join the side brackets at each end of the composite roof bow. Source | IVW and Fill

Induction and laser joining

Adjacent to the structuring cell is the joining cell, which comprises two distinct operations: induction joining of the center bracket and laser joining of the left and right side brackets. “For larger parts with a moderate complexity like the center bracket, induction joining is a more suitable joining method,” says Weidmann. “A ceramic consolidation tool with inductor applies pressure on the joining area and is permeable for the electromagnetic field, leading to an efficient energy input into the metal bracket for heating. This is convenient for flat shapes, but more challenging for complex shapes, such as the geometry of the side brackets. Thus, it was more effective to use laser joining for these.” Weidmann adds, “Induction joining is best for large parts and moderate complexity, while laser joining is more suitable for parts with high complexity.”

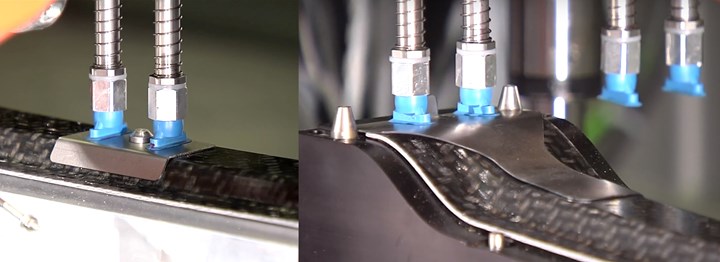

A drilled hole in the composite roof stiffener aligns it on top of the support tooling, shaped to match the curvature of the thermoformed stiffener. A laser-cut hole in the center bracket locates it on the roof stiffener while the side brackets are aligned by their shape which matches the ends of the roof stiffener.

“The center bracket was joined using discontinuous induction joining. “This is essentially quasi-static press joining,” says Weidmann, “which simply means it is a static process, achieving an areal join in one place, but there is movement in the z-direction because the thickness of the composite changes slightly due to the consolidation pressure applied during (induction) joining.”

The induction joining unit contains a KGR (Brandizzo, Italy) high-frequency generator to supply an alternating electric field to the induction coil. The head is moved via an electric motor and spindle (Fig. 3) so that the ceramic consolidation tool presses down onto the metal bracket. The induction coil in the consolidation tool causes the metal to heat, which melts the composite matrix and creates the joint. “Pressure is applied throughout heating and cooling,” notes Weidmann.

Laser joining of the side brackets begins simultaneously to induction joining. Two clamping devices, located on either side of the support tooling, can apply 4,000 Newtons of clamping force to the side brackets. “The clamping is necessary to minimize the gap between the composite and metal components,” explains Voithofer. “This prevents voids in the joint.” After the clamping force is applied, the laser head moves into position. It is equipped with a LineBeam diode laser supplied by Leister Technologies (Kägiswil, Switzerland). Johannes Eckstaedt from Leister explains that this laser has a maximum output power of 600 watts at an emission wavelength of 980 nanometers. The beam is formed to a 27-millimeter by 1-millimeter line by optical lenses, and is focused on the metal bracket. The laser head is mounted onto a robot arm that allows it to move along the shaped bracket surface. “We set different speeds for each area of the brackets to achieve a homogeneous joining temperature, reducing thermal stress for the best joining results,” says Eckstaedt.

In general, laser joining can use either transmission or heat conduction joining. For laser transmission joining, the composite being joined must be transparent for the selected wavelength of the laser. The laser then passes through the composite, hits the metal surface of the bracket and heats it. However, this method was not used in the FlexHyJoin demonstrator because the roof stiffener’s organosheet laminate was not laser-transparent. Instead, the alternative method of heat conduction joining was used. This simply applies the laser directly to the metal surface, which conducts heat through the metal base material to the composite, melting the PA6 matrix at 220-300ºC and creating the joint. “Due to the high thermal conductivity of the steel brackets, the laser heat spreads quickly, efficiently joining the side brackets,” says Voithofer.

Step 3. Inside the structuring cell, a high-power fiber laser creates undercuts in the surface of the bracket to be joined in the composite roof stiffener.

Step 5. The robot goes back to the structuring cell, picks up the treated brackets and places them, structured side down, onto the TPC roof bow.

Step 6. The robot then places clamping units on the three brackets. The induction joining unit lowers onto the center bracket. The induction coil causes the metal bracket to heat, melting the underlying composite’s PA6 matrix.

Step 7. While induction joining is completed, the laser joining unit is lowered to join the left and then right-side brackets. The laser heats the metal, causing the underlying PA6 matrix to melt into the undercuts, creating a high-strength join.

Joining process control

The basic method for controlling both joining processes is to measure the temperature and time versus a set of optimized parameters that were defined through testing. “Therefore, we produced joining test samples with different parameters and performed mechanical testing for each parameter set using special testing set-ups. For the side bracket, a combination of a shear test and peel test was developed, and for the center bracket we used a pressure load test, comparable to a lap shear test, but you push instead of pull, in order to get a shear load in the joining area,” says Popow. The set-up of these special tests was designed together with EDAG Engineering GmbH (EDAG, Fulda, Germany), which also did the analysis of the test results. Following this procedure, the best set of parameters for the joining processes were identified and then used in the pilot production cell.

“The induction joining process was calibrated ahead of time,” says Weidmann. “We know we achieve the joining temperature after approximately 30 seconds, but we also measure the temperature in-situ for safety reasons to avoid an overheating.” A pyrometer, which remotely measures a surface’s radiation, was used to measure a known hot spot in the induction joining area. “But it cannot provide accurate measurements of the laser joining due to the high level of irradiated light and heat in-situ,” he explains. However, contact sensors could be used on the composite side of the laser joining areas, though they were not applicable for the induction joining process because they are typically made of metal and would heat up by induction and distort the measurement.

“The heated areas for all of the joints are also covered by the pressing tool and clamping fixtures,” notes Weidmann. “Thus, we have validated thickness change of the component due to pressure and heat before and after joining as a quality assurance method.” This thickness change is measured by a distance sensor integrated into the positioning tool for the roof stiffener (also shown in Fig. 3). “When we press the parts together, the distance sensor is moved,” he explains. “When we apply heat and joining pressure, the molten matrix polymer flows into the cavities of the laser structuring and is slightly squeezed out of the joining zone until the joint cools. This leads to a change in thickness which is logged by the distance sensor.” Weidmann and the IVW team have correlated this distance to part quality. “A thickness change — in other words, a compaction — greater than 0.1 millimeter means the joint quality is good,” notes Weidmann.

Inline NDT

IVW developed another method for quality assurance — inline thermography testing. “For quality assurance, the main aim was to see the properties in the join area,” explains Popow. “But this was very difficult, so we performed thermography on the composite side of the joins after the part was completed.”

IVW chose an active thermography technique called Lock-In Thermography because it offers a better signal-to-noise ratio than other active methods (e.g., Pulse Phase Thermography) and can also inspect for deeper defects. “The basic idea is to put heat into the composite, which then conducts into the join area and back to the surface,” says Popow. “With Lock-in Thermography, the component is excited with a defined frequency over several periods. We then analyze this response over time. If you have areas between the composite surface and the join area which are not homogeneous due to a void or defect, it will show in the thermal response.”

The thermal response is captured as an image. The dots that comprise these images are pixels, short for picture elements. Each pixel is also a measuring point. Thus, the temperature signal for each pixel over the whole inspection area is analyzed. “As a result, you get amplitude and phase information for each pixel, and the software then reconstructs this to an image again, which can be visually inspected,” he adds. But it also provided large sets of measurements for the 126 parts tested. “We have correlated these NDT results with the results of the mechanical testing performed by EDAG,” says Popow. His team also tested the join area after removing the brackets — i.e., destructive testing. “We have thus correlated three sets of test results and can now identify low-strength versus high-strength bond areas from the visual analysis of the thermography results,” he says.

Integrated cell for mass production

One of FlexHyJoin’s greatest achievements, says Weidmann, is integrating all of the technology units, each developed by a different project partner, into an automated, optimized production line. Voithofer, the one integrating the equipment at Fill, explains that “each set of equipment shipped to us used a different controller. I had to devise a master PLC to control all of the different process units.” This included the laser enclosures and the cell’s handling robot, which were supplied by Fill. “It was also very difficult to make all of these process steps work together because they take different amounts of time,” he adds.

Voithofer began by developing an architecture for each process unit and robot, considering how to position these for the best flow. “Our concept was to keep the three stations — structuring, joining and NDT — modular, in three separate housings,” he says. “In this way, we could extract single units and use them at trade shows or other demonstration projects, and then return them. So, the work cell is modular, yet integrated.”

Fill’s decades of experience in this type of systems integration for serial composites production helped achieve what Popow sees as FlexHyJoin’s greatest feat: moving from lab-scale to industrial scale. “We are the first consortium to realize a process like this, which is suitable for mass production of composites joined to metal,” he says. “This process can be used for many automotive parts such as stabilizer links, bumpers and doors,” notes Voithofer. “There are many composite parts that connect to metal parts in a lightweight BIW.”

Adaptation for multiple industries

However, there are a few changes needed before the cell is put into serial production. “We would no longer keep the laser structuring and joining in separate enclosures, but combine them into one,” says Voithofer. “This would remove the need for enclosure doors to open and close between these processes, reducing cycle time.” He would also connect all of the stations linearly on a conveyor belt. The line would thus run continuously, with parts picked up and placed back on the conveyor for each station before exiting the cell ready for assembly into a BIW. This would further cut cycle time. Also, expanded drawers able to feed hundreds of parts would enable the line to run through whole shifts without the need for resupply.

Though this pilot production cell was targeted for the automotive industry, Popow notes it can be easily adapted to aerospace, sports/consumer goods and industrial applications. “That was actually one of the main guidelines,” says Weidmann, “that it must be able to join different geometries and parts. The only change should be the induction joining compaction tool, the clamping fixtures for laser joining and the support tooling. The main parts of the cell should stay the same.” He notes that IVW has also demonstrated hybrid joining of titanium and steel to woven carbon fiber/polyphenylene sulfide (PPS) organosheet composites and is now developing polyetheretherketone (PEEK) and polyetherketoneketone (PEKK) demonstrations. “This simply requires adapting the joining processes for higher temperatures and redefining optimum process parameters,” says Weidmann. “The cell is open to a variety of materials, including aluminum and copper as well as other thermoplastic composite matrix systems such as polypropylene and polyethylene.”

“The project partners have worked well together and are excited to go further in development,” he notes. “We think this type of production is very promising, and the response we have received from industry so far shows there are a variety of companies that see this promise as well.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More