Thermoplastics in the quest for aerospace weight savings

Safran Cabin, Victrex and Tri-Mack Plastics collaborate to migrate an aerospace storage bin from aluminum to an overmolded thermoplastic composite. The result proves the promise of thermoplastics in aerospace interiors.

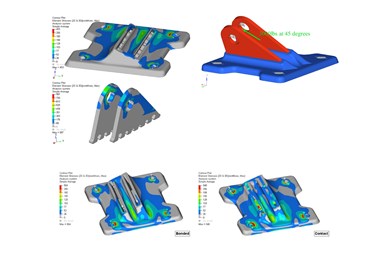

The aircraft storage bin bracket developed by Victrex, Tri-Mack and Safran Cabin integrates two carbon fiber/PAEK inserts overmolded with a PEEK resin. The result was 50% mass reduction, 20% cost reduction and substantial improvement in buy-to-fly ratio. Source | Victrex

When it comes to conversion of metallic aerostructures to thermoset composites, most of the low-hanging fruit — wing, fuselage and tail structures — has been picked. In next-generation aircraft, thermoplastic composites are sure to play a major role in large structures as well. In the meantime, however, there are conversion opportunities available today for thermoplastics .

One such part is a type rarely seen, but highly important: interior load-bearing brackets. These are the brackets (currently aluminum, stainless steel and titanium) that attach bulkheads, lavatories, galleys and luggage storage bins to the floor and fuselage of an aircraft. These brackets come in a variety of shapes and sizes, depending on what is being attached. By themselves, these brackets do not weigh very much. But, because each aircraft consumes hundreds of brackets, total weight is substantial.

Aircraft interiors specialist Safran Cabin (Huntington Beach, Calif., U.S.) recognized this and recently turned to thermoplastic composites specialist Victrex (Thornton Cleveleys, U.K.) and fabricator Tri-Mack Plastics Manufacturing (Bristol, R.I., U.S.) to convert an aluminum storage bin cabin bracket to a new design made with VICTREX AE 250 carbon fiber/polyaryletherketone (PAEK) unidirectional (UD) tape overmolded with VICTREX PEEK (polyetheretherketone) 150CA30 polymer.

Physical testing of the overmolded bracket. Source | Victrex

The bracket features a rectangular base with two vertical inserts protruding from the center of the base. The base has one molded-in hole at each corner to accommodate fasteners; each insert also has a hole near its apex, to accommodate attachment pins and other hardware. The insert is made with the carbon fiber/PAEK material; the base is overmolded with the PEEK resin.

Victrex and Tri-Mack, working with Safran Cabin, provided the materials, part design optimization, processing and tooling expertise required to realize design features and meet key performance parameters. Safran Cabin provided expertise in design and manufacturing to ensure applicability in aerospace service and certification environments.

Tim Herr, director Aerospace at Victrex, says the inserts are fabricated with a Dieffenbacher (Windsor, Ontario, Canada) Fiberforge machine, which lays carbon fiber/PAEK UD tapes to build a laminate. This laminate is press consolidated, edge trimmed and then waterjet cut to make the inserts. During waterjet cutting, each insert is scalloped at its base to create a mechanical interlock surface during overmolding.

The inserts are then placed in a tool, followed by injection overmolding of the PEEK. “When we overmold,” says Herr, “we are creating a very strong bond between the PAEK composite insert and the injection molded PEEK material.” The key for this enabler, says Herr, is the unique combination of PAEK and PEEK. The PAEK, he notes, has a process temperature about 40°C less than that of PEEK. This temperature delta facilitates an intimate and durable bond between the two parts. “Without the invention of PAEK,” Herr argues, “hybrid molding of this type would have been impossible.”

Design simulation images of bracket performance under load conditions. Source | Victrex

This design/process combination required extensive simulation, analysis, prototyping and physical testing, through which Victrex identified several design and process flaws, including insert deformation, resin flow hesitations, bond/interface failure and voids. This sent designers back to the drawing board to optimize the design, and manufacturing engineers back to the injection molding machine to do process optimization. The final design/process combination overcame these challenges and proved the viability of a thermoplastic composite overmolded bracket.

The initial prototype brackets were produced at Tri-Mack. Compared to the original aluminum part, the prototype composite achieved 20% cost savings, 50% weight savings and a 5x better buy-to-fly ratio.

"We need to respond to many demands for aircraft brackets and similar structural parts, with each case having many loading, constraint, and exposure conditions," says Tyler Smithson, R&T Engineer at Safran Cabin. "The key to success is to develop a flexible composite platform that can be used for multiple projects, lowering our part count and design complexity, cutting time-to-market, speeding time-to-revenue."

Victrex says the hybrid overmolding process is a scalable, repeatable technology that has potential to help commercial aerospace customers reduce scrap rates, speed cycle times, boost part consolidation and reduce secondary operations.

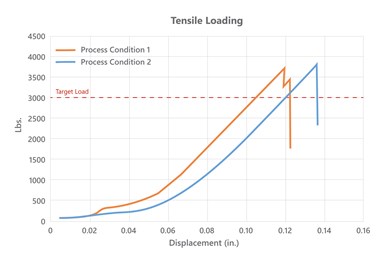

Test results following the second design iteration of the bracket showed substantial improvement in load limits and failure conditions. Source | Victrex

"At Victrex, we are proud of our track record in introducing 'disruptive' technological approaches in the sectors that we serve, using our know-how in the processing and performance of PAEK materials to accelerate the commercialization process," comments Herr. "Hybrid overmolding and VICTREX AE 250 composites are certainly within this category but this is just the beginning. We continue to test our composites offering, with support from our customers and partners in order to demonstrate the full potential of these materials.”

Currently the bracket is scheduled for final testing and qualification of production parts. “The goal, is to put the composite bracket in service later in 2019. We have done all we can to demonstrate this bracket can perform,” Herr says.

Victrex’s Frank Ferfecki, Safran’s Tyler Smithson and Tri-Mack’s Chris Bjerregaard are giving a presentation on the development of the Safran hybrid bracket at CAMX 2019 at the Anaheim Convention Center (Anaheim, Calif., U.S.) on Tuesday, Sept. 24, 2:30 pm, in room 201D

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More