Curing

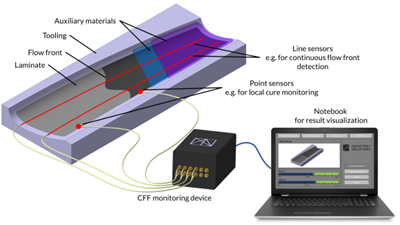

Sensors for monitoring resin infusion flow front and cure

InFactory Solutions commercializes technology to provide real-time resin impregnation and cure data across composite parts for zero-defect, intelligent process chains.

Read MoreComposites give shape to new passenger bus

The VDL Bus & Coach Citea bus features composite structures fabricated using a vacuum expansion process (VEX) with specially formulated foaming resin compounds supplied by BÜFA Composite Systems.

WatchZero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

WatchWisconsin Oven doubles manufacturing space

The company has added 130,000 ft2 of new space with the acquisition of a neighboring building in East Troy, WI, US.

Read MoreSpirit AeroSystems unveils new composites curing technology

Spirit’s research group in Scotland has developed an “intelligent heated tool” technology that obviates the need for the autoclave and reduces cure time by 40%.

Read MoreADEKA, GH Craft develop fiber-to-composite direct process

The FtoC molding process automates resin impregnating, curing and laminating processes while aligning highly oriented fibers.

Read MoreDelta Airlines installs LEWCO composite curing oven

The curing oven will be used to manufacture parts for Delta’s airplane cabins.

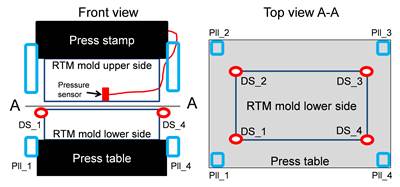

Read MoreFraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

Read MoreCAMX 2017 preview: Epcon Industrial Systems

Epcon Industrial Systems (The Woodlands, TX, US) is featuring its industrial ovens and furnaces for curing, paint finishing, burn-out, heat treating, annealing and aging.

Read MoreUnweighting a crane to increase payload limit

Rethinking a crane stinger with carbon fiber for a more “uplifting experience.”

Read More