Curing

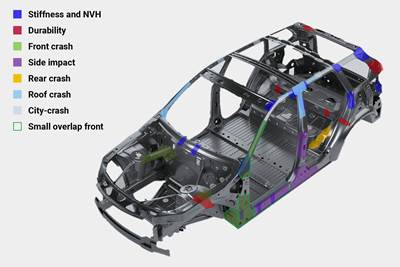

Composites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

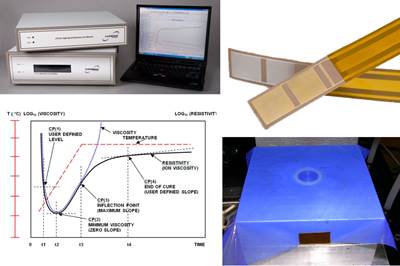

Read MoreCombining AC and DC dielectric measurements for cure monitoring of composites

Lambient Technologies advances dielectric analysis (DEA) for more reliable, affordable composites manufacturing.

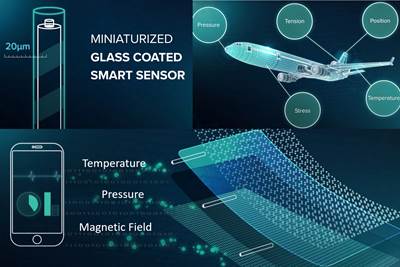

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchTPS ships Gruenberg vertical conveyor oven, meets specific customer needs

Stainless steel internal chamber, operating temperature of 270ºF and an installed high-volume, 6135 CFM horizontal airflow system.

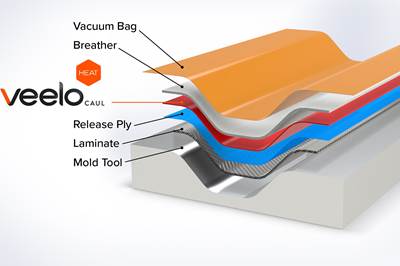

Read MoreVeeloHEAT Caul enables in-situ hot debulking capabilities

Built on existing debulk bagging procedures, Veelo Technologies’ debulking solution can take place at the tool during layup, reducing costs and improving throughput.

Read MoreBespoke process produces composite brake pedal every minute

Three composite materials are used to create structural composite member that meets demanding mechanical requirements.

Read MoreVastek Industrial showcases tabletop infrared conveyor oven

Ideal for laboratory testing and low-volume production applications, the D-100 model is highly compact, and ensures edge-to-edge temperature uniformity.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

Read MoreAdapa, ElectroHeat partner for reconfigurable thermoforming solution

Off-the-shelf solutions will pair curing oven and reusable adaptive mold to fit standard panel sizes for lower-cost composites manufacturing.

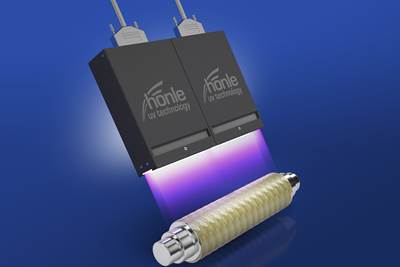

Read MoreTechsil, Panacol offer Vitralit adhesive for filament winding

The transparent one-component epoxy adhesive and curing system is ideal for carbon fiber or glass fiber filament winding.

Read More

.jpg;maxWidth=300;quality=90)