Curing

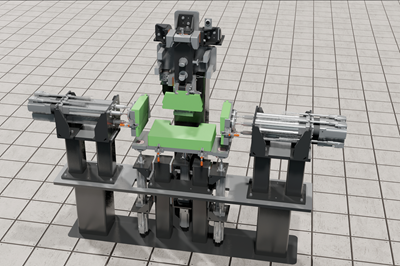

Fast-FlexMont2 project targets optimized, large-structure CFRP assembly

Advanced measuring and referencing methods, highly precise positioning technologies and continuous digital process control by Fraunhofer IFAM demonstrate automated rudder hinge assembly.

WatchCAMX 2022 exhibit preview: Thermal Equipment Corp.

TEC highlights its range of services and capabilities, including its Off-The-Shelf (OTS) Autoclaves which deliver robustness, quality and reliable performance.

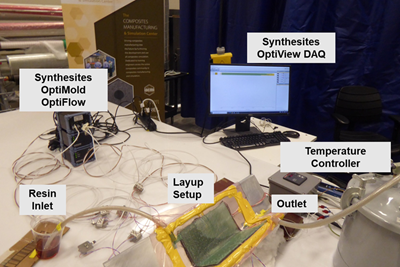

Read MoreSynthesites, Purdue CMSC advances real-time cure monitoring

Partners are developing cure simulation using data from dielectric sensors to monitor infusion and autoclave composite structures in real time.

Read MoreCAMX 2022 exhibit preview: BriskHeat Corp.

BriskHeat manufactures a full line of heaters and temperature controllers, designed to solve a variety of composite curing, repair applications.

Read MoreCAMX 2022 exhibit preview: Bondtech Corp.

Bondtech offers industry attendees an extensive selection of autoclaves, pressure vessel solutions and services.

Read MoreHORYZN emergency UAV harnesses CFRP tooling from Voith Composites

Voith Composites collaborated with HORYZN, a student initiative that leverages CFRP tooling and composites know-how for its Mission Pulse UAV project.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreSaint-Gobain, Roctool join efforts to boost composite 3D textile preform parts manufacturing

3D automated knitted preform layup technology and heat and cooling technologies for additional curing efficiency open a new window of application opportunities for composite and thermoplastic parts.

Read MoreHaydale Graphene awarded Innovate UK grant to develop smart composite tooling

The ESENSE project aims to replace costly autoclave processes with a multi-zone OOA self-heated tooling solution, potentially cutting lead times by 20%, energy by 15% and halving the cost of autoclave manufacturing.

Read MoreClassic Recreations announces carbon fiber bodied Shelby Cobra race car

The officially licensed 1965 CSX Shelby Cobra race car features an autoclave-cured carbon fiber body, including the floor and doors, and is said to rival supercars in weight and horsepower.

Read More