Curing

Plant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

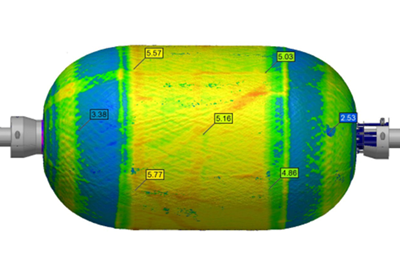

Read MoreNCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

Read MoreHengshen to produce rear pressure bulkhead demonstrators

China-based Hengshen Carbon and Composites will produce five 4.5-meter demonstrator composite rear pressure bulkheads (RPB) for a Chinese aerospace OEM.

WatchLewco supplies custom composites curing ovens for aerospace

Lewco Inc. recently supplied ovens to three customers ranging from a research laboratory to an aircraft manufacturer.

Read MoreHarper International expands product offering with lab-scale rotary furnace

The furnace delivers temperature uniformity for batch or continuous processing of advanced materials at at operating temperatures up to 1,200°C.

Read MoreHexcel, HP Composites develop carbon fiber Class A body panels

Italian component producer combines composites processing expertise with Hexcel HexPly XF3 surfacing material, HexPly M47 and HexPly M49 prepregs for supersport sedan external body panels.

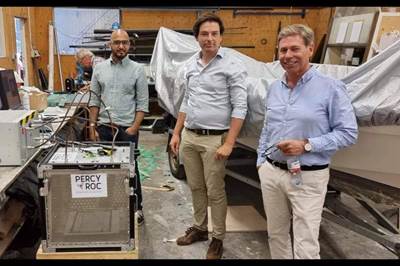

Read MorePercy Roc's microwave curing system passes the test

Percy Roc’s curing process is monitored using infrared technology, which means that the heating is regulated in real time so that the entire surface can be heated homogeneously.

Read MoreNotus Composites launches low-temperature curing epoxy prepreg

NE7 formulation enables composite manufacturers to cure components at temperatures as low as 70˚C, reducing energy consumption and enabling more cost-effective tooling options.

Read MoreLohmann expands reactive chemistry adhesives line

Lohmann Corp. & Subsidiaries launches UV-LUX, a UV light-activated adhesive that changes changes colors as it adheres and cures, indication chemical progression.

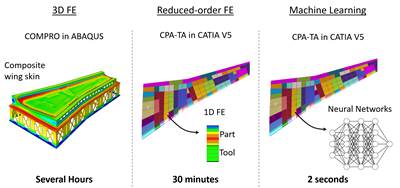

Read MoreUsing machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

Read More

.jpg;maxWidth=300;quality=90)