Design & Tooling

Two visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

WatchPushing the limits of infusion

Polyworx BV used RTM-Worx, semipermeable membranes, a special feed and vacuum line layout and MMD machines to infuse a 62m minesweeper with degassed resin.

Read MoreVIDEO: Helicopter Drop Test

NASA evaluates composites’ ability to improve helicopter crashworthiness by dropping a helicopter fuselage to simulate a severe survivable crash according to military and commercial transport requirements.

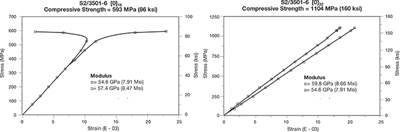

WatchBuckling of composite material compression specimens

Dr. Donald F. Adams (Wyoming Test Fixtures, Salt Lake City, Utah) rehearses the causes of, and solutions for, problems with buckling in composite compression specimens.

Read MoreBus station pavilion: A marriage of design and manufacture

Architectural design studio and boatbuilder cooperate to make this passenger terminal "first" a first-class showpiece.

Read MoreABCs of ultrasonic inspection

A primer on nondestructive ultrasonic inspection technology.

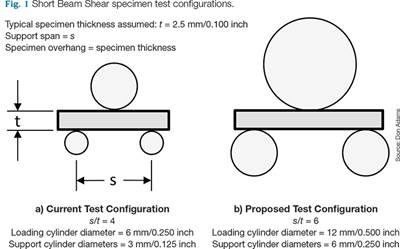

Read MoreThe Short Beam Shear test method for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) suggests larger support and loading cylinders for the Short Beam Shear test method.

Read MoreMaximum thrills: Minimal tools

Water slide manufacturer’s disastrous fire loss opens door to a closed molding process that reduces the number — and cost — of production molds, promising future gain.

Read MoreTooling up for larger launch vehicles

NASA and Janicki Industries demonstrate composites’ cost advantage in tooling for fabrication of 10m/33 ft diameter payload fairing for next-generation launch vehicle.

Read MoreOptimization software improves small, low-cost satellite design

Ames Research Center’s (Moffett Field, Calif.) designs and builds a low-cost, small spacecraft on a quick turnaround, using a modular strategy based on commercial off-the-shelf (COTS) parts and with the aid of several design software packages and finite element solvers.

Read More