Design & Tooling

Out-of-autoclave processing: <1% void content?

Research sheds light on air and air-bubble behavior in OOA aerospace prepregs.

Read MoreHeated composites

LaminaHeat enables heated composite tools and new opportunities for composites via multifunctional structures.

Read MoreMassive, bondline-free tooling block

A candidate for the biggest “bun” from high-density urethane foam?

Read MoreVirtual process chain + online process monitoring = first-time-right manufacturing

Co-authors Dr. Michael Bruyneel, Marc Attar and Dr. Christian Brauner (Siemens PLM Software, Liège, Belgium) illustrate the benefits of manufacturing simulation software in virtual trials of molding processes, using resin transfer molding as a reference.

Read MoreWeber Manufacturing Technologies: Midland, ON, Canada

With a long, storied history in composites moldmaking, this rare nickel vapor deposition specialist has built a strong niche, making large, high-quality tools.

Read MoreAscent Tooling Group ascends via innovation

The world’s largest metal and composite moldmaker has a new name and continues to make a name for itself in closer control of large-part dimensional tolerance.

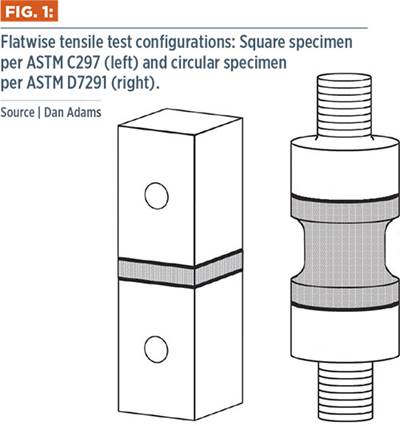

Read MoreMethods for interlaminar tensile testing of composites: A comparative evaluation

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) compares and contrasts the direct and indirect loading methods for interlaminar tensile testing of composites.

Read MoreCompoSIDE delivers cost and time saving for composites consultancy

STRUCTeam cites £40,000 savings in licensing costs and up to 40% reduction in design time by using this web-based composites design engineering solution.

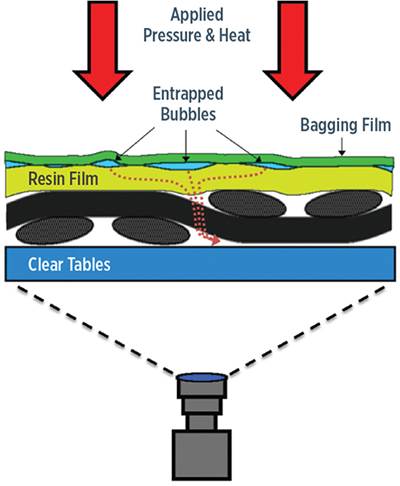

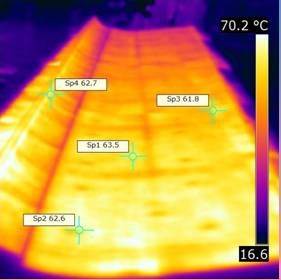

Read MoreIntegrating NDI into manufacturing: Online inspection of CFRP prior to cure

Esmeralda Cuevas, head of NDT technologies at Tecnatom SA (San Sebastian de Los Reyes, Spain), details efforts of the TARGET project, which investigated how to integrate NDI into the composites manufacturing process prior to cure stage.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read More

.jpg;maxWidth=300;quality=90)