Design & Tooling

Incremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

Read MoreQuasi-isotropic, symmetrical fabric for tooling

Well-known in structural applications, this symmetric, balanced and quasi-isotropic fabric offers savings and opens opportunities in composites tooling.

Read MoreMoldmaker bypasses patterns for high-tech production catamarans

Direct-to-milled-tool process simplifies large deck mold development.

Read MoreGetting part dimensions right in composites molding

Guest columnists Dr. Göran Fernlund (left) and Dr. Anoush Poursartip (right) of Convergent Manufacturing Technologies (Vancouver, BC, Canada) argue that today's CAD design and process simulation software can construct a "multi-physic process model" accurate enough for reliable dimensional management.

Read MoreModeling and simulation: Is ICME the next composites breakthrough?

CompositesWorld columnist and composites industry consultant Dale Brosius encourages empirical learners (read "hands-on, trial-and-error old-timers") like himself to buy in and start using today's software-based design and simulation tools, which, he says, have the "potential to truly transform the composite industry."

Read MoreComposite tooling without oven or autoclave

No Oven No Autoclave technology has been demonstrated in tooling for NASA, including multiple thermal cycles and use for curing epoxy infused out-of-autoclave parts.

Read MoreTooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreTools for collecting, managing and using autocomposites data

As the composites universe expands into new markets and applications, resins and fiber reinforcements of many types are, increasingly, landing on the desks of design engineers who have little or no experience with composites.

Read MoreMaterials library seeks composites industry submissions

If you’re a designer for Adidas, Motorola or Toyota, where do you get information about cutting-edge material developments?

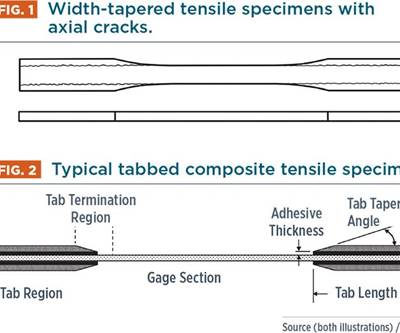

Read MoreTensile testing composites: Simple concept, difficult in practice

Dr. Daniel O. Adams, professor of mechanical engineering and director of the Composite Mechanics Laboratory at the University of Utah, and the vice president of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), takes over for his father, Dr. Donald F. Adams, as the anchor writer in CompositesWorld magazine's revamped CW Design and Testing column. First subject? The challenges of tensile testing unidirectional composites.

Read More

.jpg;maxWidth=300;quality=90)