Design & Tooling

Why standardize composites test protocols?

Every column I write for HPC eventually refers to “standard” test methods. But why are standards written? What groups promote these standards, and who actually writes them? Most importantly, why do the rest of us need to follow their standards, and what if we don’t? To answer the first question, we must step back into

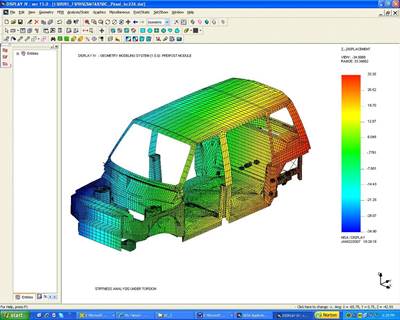

Read MoreFEA Roundup: Design, Simulation And Analysis Converge

New modeling and analysis software products increase the accessibility and reliability of finite element analysis data.

Read MoreTesting Tech: Adhesion testing of sandwich panels

In my three preceding columns, I discussed the testing of sandwich panels as unit structures. This included flexural and shear testing of beams and panels. However, such tests — and hardware components that are designed accordingly — will not produce the desired results unless the adhesives that hold these panels

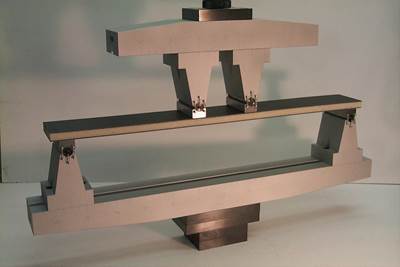

Read MoreTesting Tech: Shear testing of sandwich panel core materials

In my previous column (HPC November 2006, p. 10), I noted that the shear strength and shear stiffness of the core material in a sandwich panel can be determined in situ while performing flexural tests to evaluate other sandwich panel properties. However, as was stated then, it is more accurate to measure these

Read MoreSandwich panel flexure testing

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) comments on the composite materials testing community's move toward the use of the terms "long beam flexure" and "short beam flexure" when addressing sandwich panel testing.

Read MoreSandwich panel test methods

This column will introduce sandwich panel test methods in general. Detailed discussions of the individual test methods will be presented in future columns. Sandwich panels will be defined here as those consisting of relatively thin facesheets that are strong and stiff in tension and compression compared to the low

Read MoreSoftware Secures Lighter, Stronger, Safer Airframe

The U.S. Air Force Research Lab (AFRL) Air Vehicles Directorate is pursuing high-speed aerospace system concepts that include the LRS (Long Range Strike) aircraft. The LRS is to fly at Mach 3.5 and is in the concept definition stage, planned for military utility in the 2020+ timeframe. The lab's goals are to

Read MoreJEC Composites 2006 Product Showcase - 7/1/2006

Advanced composites continue to lead the economic upswing in the composites industry.

Read MoreSky's The Limit For Composites-intensive UAVs

Market growth is being spurred primarily by post-9/11 combat actions, homeland security and natural disasters.

Read MoreBack-out factors

Dr. Adam's follows up a previous column, in which he discussed the advantages of testing a cross-ply laminate and then "backing out" the unidirectional composite strength, with an expanded examination of back-out factors that can be applied to other types of laminates.

Read More

.jpg;maxWidth=300;quality=90)