Design & Tooling

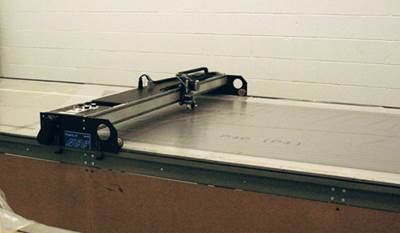

Upsizing blade test regimes

As composite rotor blade size grows, research groups act to meet the urgent need for physical testing facilities with large-blade capacity.

Read MoreVery Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

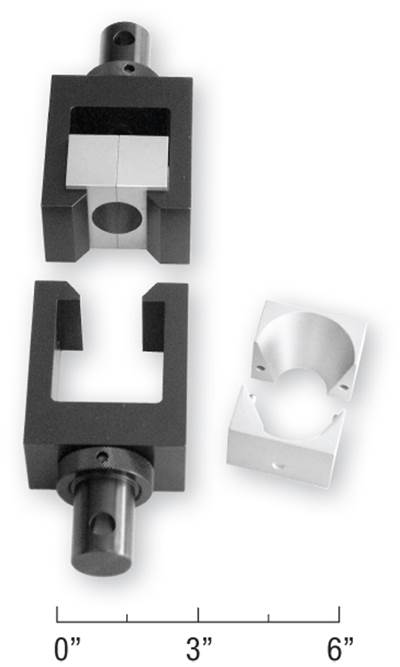

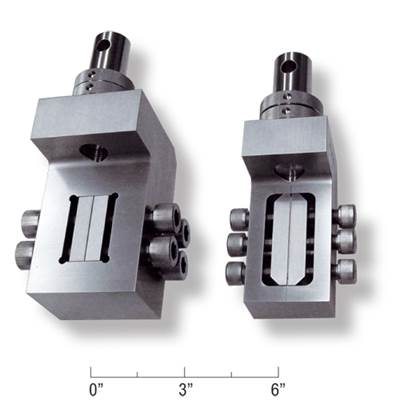

Read MoreAdditional grip types for tensile test specimens

Dr. Don Adams follows up a previous discussion of wedge grips for testing tensile specimens with a sampling of other grip types.

Read MoreGurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

Read MoreRTM showcase: One-Piece Rudder

A transatlantic design team uses concurrent engineering to integrate rudder spars, ribs and skins in a single RTM cycle.

Read MoreAdvanced Composite Cargo Aircraft proves large structure practicality

Dr. John Russell reports that the successful completion of a flying aircraft in the the Advanced Composite Cargo Aircraft program has demonstrated the holistic impact that composites technology can have on future aircraft development.

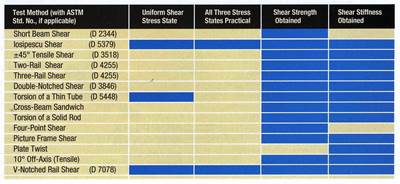

Read MoreShear test methods: Iosipescu vs. V-Notched Rail

Dr. Don Adams asks and suggests a likely answer to the question Which shear test method is best?

Read MoreA comparison of shear test methods

Dr. Don Adams compares the shear test methods that are currently available to the composite industry.

Read MoreFree-form surfacing optimizes free-style kayak

The 6-ft/1.8m-long Project 54cx kayak, made using aramid and carbon fabric-reinforced composites, weighs only 19 lb/8.6 kg.

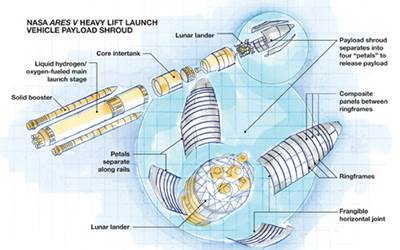

Read MoreOptimizing the Ares V payload shroud

Sizing software allows rapid analysis of candidate composite architecture for highly loaded and weight-sensitive launch vehicle component.

Read More

.jpg;maxWidth=300;quality=90)