Design & Tooling

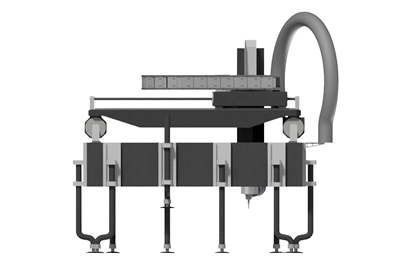

Lifting arm concept and automated repair training to propel portable repair system

Looking to commercialize its Portable Scarfing/Composite Repair System concept, AGFM and partners offer specialized training, lifting and inspection systems.

Read MorePredicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

Read MoreSABIC, Dongfeng Motors produce composite truck-mounted toolbox

Thermoformed glass fiber-reinforced PP laminate inserts are overmolded with Stamax resin for a 30% lighter part.

Read MoreTRB Lightweight Structures contributes composite bodyshell design to passenger train demonstrator

The Revolution VLR (Very Light Rail) passenger vehicle serves to simplify existing rail networks and reopen historical lines, while adhering to rigorous rail and sustainability regulations.

Read MoreSumitomo Bakelite eAxle demonstrator drives forward novel thermoset composite material applications

The fully functional eAxle, a single, compact unit that directly powers electric vehicles, will showcase the project’s newly developed materials and assemblies and validate efficiency improvements and increased design flexibility.

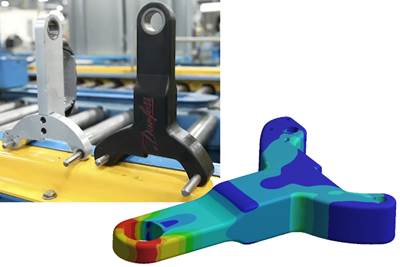

Read MoreHow to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreResin-infused center console boat configuration proves higher performance, speed, quality

Hayaari Marine employs a revised infusion setup using semi-permeable membranes to eliminate porosity and improve laminate consolidation, reducing about 450 kilograms of resin per boat, and offering 20% weight savings.

Read MoreComposite-metal anti-roll bars make headway for lightweight automotive suspension systems

The LiMeCH project, led by the AMRC, Tinsley Bridge and Performance Engineered Solutions, developed filament-wound CFRP-metallic roll bar prototypes, with additional advances in joint bonding the hybrid materials.

Read MoreJoby begins first conformity test, enters next phase of certification process

First series of conformity tests were completed at Toray Advanced Composites’ U.S. facility, with thousands more to be performed to achieve type certification of the composite eVTOL.

Read MoreProtocol aims to improve testing of thermal runaway for composite EV battery enclosures

Hyundai-Kia and Forward Engineering developed a resistive, heater-based material test, recently published as a UL standard, to aid and speed composite battery enclosure development.

Read More

.jpg;maxWidth=300;quality=90)