Design & Tooling

Hybrid analysis: Making the most of FEA by leveraging traditional analysis

CW guest columinst Collin Petersen (Janicki Industries, Sedro-Woolley, WA, US) suggests the use of more traditional analysis methods, where it is sensible to do so, making your finite element analysis (FEA) significantly simpler in the process.

Read MoreNCDMM, Ingersoll, Orbital ATK complete automated composites inspection system

The Automated Composite Structure Inspection System achieved a defect detection rate of up to 99.7% on aircraft components produced via automated fiber placement.

Read MoreBoat builder Lyman-Morse creates aerospace composite prototype

Prototypes for such clients as the Department of Defense and other government and private sector businesses has become an increasingly important segment of the the company’s business plan.

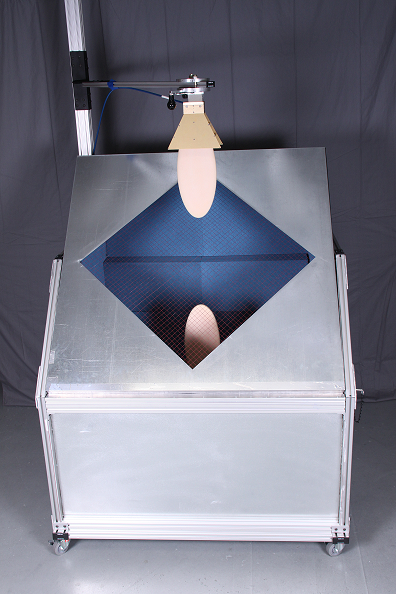

Read MoreDielectric properties measurement drives this NDT system to composites market

Material-Wave Interactions Laboratories (MWI Lab, Tempe, AZ, US), a 2010 spin-off of nondestructive material inspection technology developed at Arizona State University (Tempe), is coming off a period of substantial R&D and is preparing to put its product into the composites fabrication and maintenance and repair market.

Read MoreV-notched shear testing of composites

Dr. Daniel O. Adams, professor of mechanical engineering and director, for 18 years, of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), reviews the most popular V-notched shear test methods for composite materials.

Read MoreSlideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

Read MoreDielectric properties measurement drives NDT technology to composites market

Material-Wave Interactions Laboratories is ready to put its nondestructive, in-process quality control and lab-based antennas into the market; they measure anisotropic/dielectric/magnetic material properties at high scpeeds.

Read MoreSPE ACCE 2015 show report

Was this the year, finally, for the big break-through for automotive composites? Maybe, depending on to whom one talked or the presentation one heard.

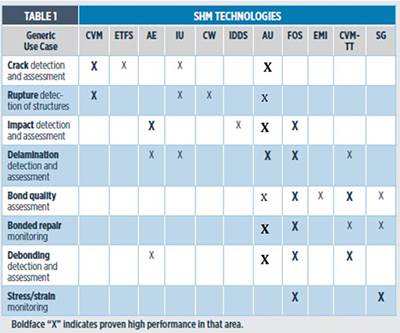

Read MoreStructural health monitoring: The toolbox

There are a broad range of SHM technologies that take advantage of a variety of sensing mechanisms. Here's a short sketch of each, accompanied by tables that indicate current uses and developmental progress.

Read MoreStructural health monitoring: NDT-integrated aerostructures

SHM moves from structural testing to an FAA-qualified inspection alternative, to reduce cost, streamline operations and mature toward lighter, more robust smart structures

Read More

.jpg;maxWidth=300;quality=90)