Design & Tooling

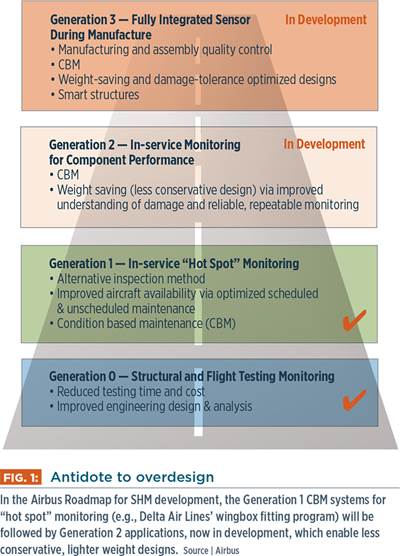

Structural health monitoring: Decades of demos build confidence

Current momentum in local structural health monitoring development can be credited to a great deal of developmental effort on the part of these system developers.

Read MoreDesigning with composites: Optimizing for performance and manufacturing

David Leigh Hudson, the director of product and market strategy for the Fibersim product portfolio at Siemens PLM Software (Waltham, MA, US), the need in the field of composite part design for a serious commitment to what he terms "concurrent engineering" processes.

Read MoreShelby GT350R features carbon fiber wheels

Ford worked with Australia-based Carbon Revolution to develop the one-piece all-carbon fiber wheels, which save 60 lb in weight but provide better steering response.

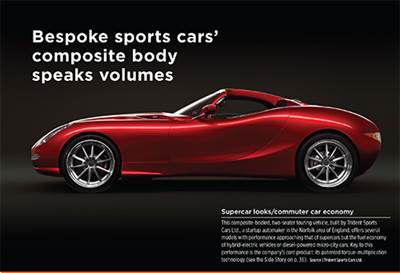

Read MoreBespoke sports cars’ composite body speaks volumes

Glass-reinforced plastic artfully captures classic curves, crash-protects passengers and stunningly packages its maker’s high-performance but highly fuel-efficient diesel powertrain.

Read MoreAdditive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

Read More3D-printed fixtures & jigs

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Additive manufacturing, therefore, is proving especially useful in reducing the design/build time/cost in this area.

Read MoreA growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

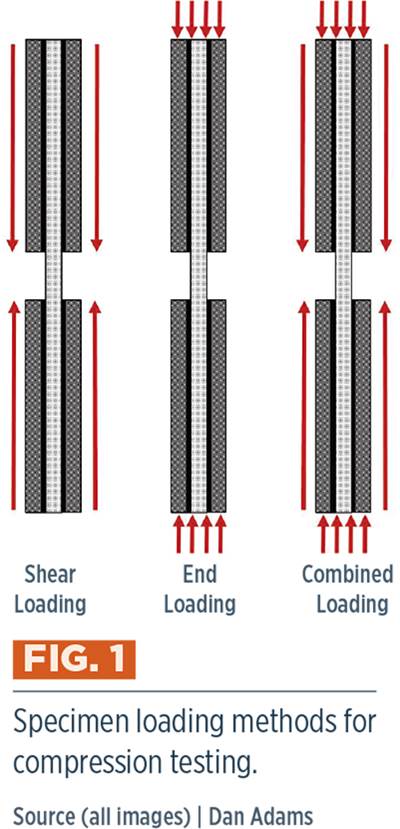

Read MoreOptimum unidirectional compression testing of composites

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and compression testing, and how best to perform the latter.

Read MoreIndiana Manufacturing Institute breaks ground

The Indiana Manufacturing Institute (IMI) is part of a $50 million project where Purdue University will advance research of composites manufacturing.

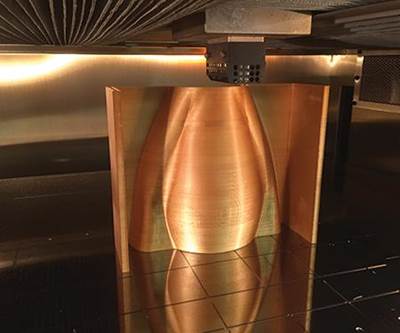

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read More