Markets

Composite flywheels: Finally picking up speed?

A wave of new composite flywheel developments for bus, rail, auto, heavy truck, construction equipment, and power grid support promises fuel savings, improved efficiency and reduced emissions — i.e. sustainability in the global quest for more energy.

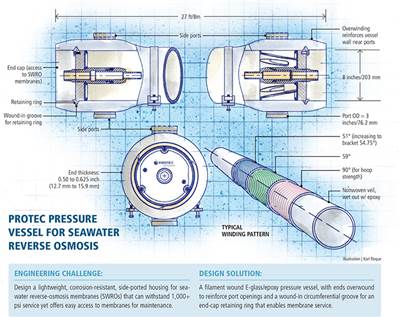

WatchDesigning pressure vessels for seawater desalination plants

Safe high-pressure service challenges manufacturers of composite pressure vessels.

Read MorePipes vs. vessels

CT editor-in-chief Jeff Sloan notes the value of composite pressure vessel standards in the growing market for seawater desalination.

Read MoreCutting train doors with precision

GFMI Aerospace & Defense uses waterjet cutting technology to produce glass fiber/epoxy door panels for a major rail car manufacturer.

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

Read MoreThe first commercial Type V composite pressure vessel

Composites Technology Development's first commercial tank in the Type V category presages growth of filament winding in storage of compressed gases.

Read MorePressure vessel tank types

Pressure vessels have been classified in four categories, based on their construction. Each type has assets and liabilities.

Read MoreCarbon fiber market: Gathering momentum

All signs point to increasing demand from many market sectors. Will capacity keep pace?

Read MoreLightweighting a heavyweight

Process combination produces significantly lighter overhead storage bins for big-rig sleeper cabs.

Read MoreTeam-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

Read More