Materials

High-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

Read MoreCannon Ergos collaborates with Boeing to mold thermoplastic aircraft sidewall panels

Mold trials study the feasibility of using recycled carbon fiber, whether impregnated with diverse resins, or already integrated within a thermoplastic matrix.

Read MoreIsotruss expands carbon fiber cell tower operations with new facility in Phillipines

Plant to produce IsoTruss products for telecom infrastructure market in southeast Asia.

Read MoreBM Composites announces the launch of the Linx 30 Superyacht Tender

The first custom tender brand designed and made in Mallorca, Spain, highlights the customizable Linx 30, a carbon fiber infused superyacht with 30-40% improved fuel efficiency.

Read MoreElixir autoclave investment brings all aircraft production in-house

The company now controls the entire production process for its aircraft, including the Elixir 915iS Turbo with a carbon fiber OneShot structure.

Read MoreRocket Lab successfully deploys four Alba Orbital PocketQubes into circular orbit

A new goal for the carbon fiber-reinforced 3D printed nanosatellites was achieved, including a sun synchronous orbit and a successful recovery mission.

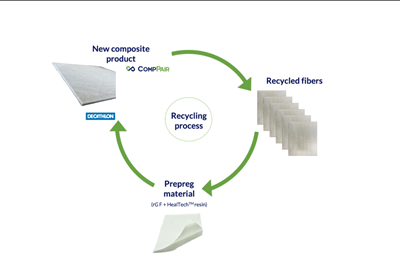

Read MoreCompPair and Decathlon successfully complete composite recycling project

Manufacture of a shoe sole demonstrated the reclamation of continuous fibers with more than 80% of their original flexural strength. Both companies are now seeking additional recycling partners.

Read MoreFairmat reaches agreements with Siemens Gamesa, Duqueine, Tarmac Aerosave to recycle composites

Recycled carbon fiber derived from wind turbine blades and aircraft will be transported and analyzed at Fairmat’s facility for consideration in repurposed products.

Read MoreDecomBlades consortium releases specifications for disposal of composite wind blades

The Product Disposal Specifications aim to help industrialize wind blade recycling, detailing materials and components of Siemens Gamesa, Vestas and LM Wind Power blades.

Read MoreClemson Composites Center: Working with industry to transform composites

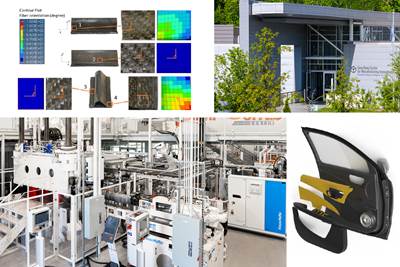

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read More