Fairmat reaches agreements with Siemens Gamesa, Duqueine, Tarmac Aerosave to recycle composites

Recycled carbon fiber derived from wind turbine blades and aircraft will be transported and analyzed at Fairmat’s facility for consideration in repurposed products.

Photo Credit: Getty Images

Deep-tech company Fairmat (Paris, France) has made several strides toward carbon fiber composites recycling in May 2022 including its first agreement with Siemens Gamesa (Hamburg, Germany) to recycle composite waste from one of the company’s sites in Denmark; a development partnership with the industrial company Duqueine Rhône-Alpes (Civrieux, France), a manufacturer of composite parts for the aeronautical, automotive, medical and sports and recreation industry; and an R&D contract with France-based Tarmac Aerosave, known for its storage, maintenance, transition and recycling of aircraft. These are all add-ons to Fairmat’s original announcement back in Nov. 2021 aiming to recycle Hexcel (Stamford, Conn., U.S.) carbon fiber prepreg.

Under the announced R&D agreement with Siemens Gamesa, Fairmat will collect the composite waste deriving from the manufacturing of wind turbine blades at a Siemens Gamesa production site in Aalborg, Denmark. The waste will next be transported to Fairmat’s production site, FairFactory, located in Bouguenais, to be given a second life in markets such as automotive, mobility, sport and construction.

Following the results of the R&D collaboration, Fairmat and Siemens Gamesa will evaluate the establishment of an ongoing collaboration on the recycling of carbon fiber-reinforced composite waste parts from Siemens Gamesa’s manufacturing processes.

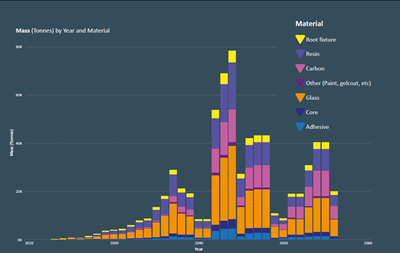

“At Siemens Gamesa we are committed to the transition to a circular economy. We have a desire to minimize the waste from our processes and products, and we rely on partners like Fairmat in our strategic development,” Jonas Jensen, sustainability specialist for Siemens Gamesa, says. “The use of carbon [fiber] composites in the construction of wind turbine blades is likely to increase in the next generation of wind turbines, and it is of utmost importance to SGRE to have sustainable solutions in place to handle the waste materials for this coming volume.”

The company’s new commercial partnership with Duqueine Rhône-Alpes, on the other hand, will enable Fairmat to recycle its production waste, particularly the materials that were used to manufacture the Airbus A350.

Fairmt is expected to recover around 15 tons of waste per year from the Duqueine sites in Massieux and Civrieux, especially from trimming, as well as from “raw” material. The production waste will similarly be transported and repurposed like that of the Siemens Gamesa material waste.

Fairmat believes the partnership represents a supply in carbon fiber-reinforced composites that will strengthen its national operations.

In addition, a major R&D contract signed with Tarmac Aerosave, a subsidiary of France-based Airbus, Safran Aircraft Engines and Suez, will see carbon fiber recycled from end-of-life (EOL) aircraft. Fairmat will also be recovering and analyzing them for possible second life.

If this is successful, Fairmat says it could lead to the signing of a commercial agreement with Tarmac Aerosave for the industrial recovery of all the parts made of carbon fiber-reinforced composites.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

Viable routes to recycling wind turbine blades found in NCC’s sustainable wind research program

Launched SusWIND program aims to establish a viable circular supply chain to tackle the main challenges of legacy and future composite blades in the U.K.

Read MoreDecomBlades consortium releases specifications for disposal of composite wind blades

The Product Disposal Specifications aim to help industrialize wind blade recycling, detailing materials and components of Siemens Gamesa, Vestas and LM Wind Power blades.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More