Materials

Sicomin bioresin used in NOTOX boards

Sicomin (Châteauneuf les Martigues, France) and surfboard manufacturer NOTOX (Anglet, France) have created a bioresin formulation that offers as little environmental impact as possible and supports greener production methods.

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

Read MoreAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchNASA exploring using carbon nanotube for aerospace applications

NASA worked with Nanocomp to produce carbon nanotube (CNT) fibers to fabricate a carbon nanotube Composite Overwrap Pressure Vessel.

Read More3D TPC structural preforming process lightens car doors

Automated cell manufactures and pre-impregnates continuous-fiber 3D preforms for injection/compression overmolding of parts with complex shapes, and tailored structural properties.

Read MorePreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

WatchComposites recycling is gaining traction

Although CW’s coverage of composites recycling dates back over a decade, informal statistics still show that only ~2% of composites-related companies are active recyclers. That said, three years since our most recent feature on the subject, there is demonstrably greater interest and activity, and real applications of recycled fiber are growing.

WatchComposites at AIA 2017

The ACMA Architectural Division exhibited its 4th annual Composites Pavilion and 2nd annual COMPOSITES CHALLENGE for architectural students.

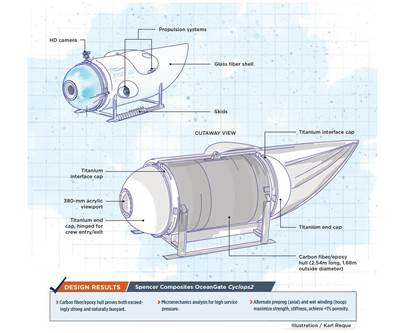

WatchComposite submersibles: Under pressure in deep, deep waters

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,500-psi service pressure.

Read MorePolyurethane’s processing speed, properties enable bigger blades

Decade-long development effort reaches key wind energy cost-reduction milestone using epoxy-besting infusion resin.

Read More