Materials

Medical applications: A healthy market

Composites make advances in devices for medical diagnosis and treatments that promote healing and help return patients to active lives.

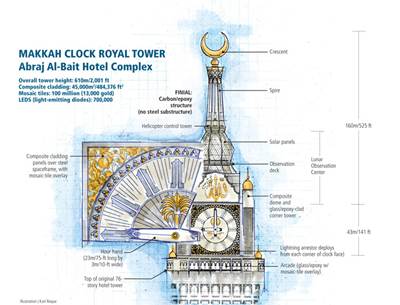

Read MoreBesting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

Read MoreNew MIL antiballistics standard

New military specifications for unidirectional thermoplastic laminates used in antiballistics applications are circulating in draft form for comments and should be completed by year’s end.

Read MoreHybrid Enhanced Combat Helmet enters final testing phase

The U.S. Army and Marine Corps are conducting final validation testing of the U.S. military’s next-generation — and radically new — thermoplastic composite Enhanced Combat Helmet (ECH).

Read MoreBuilding on CCM lessons learned

Knowledge gained during NASA's composite crew module (CCM) program, a sidelight to the Orion space capsule program, now benefits private space efforts.

Read MoreThe Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

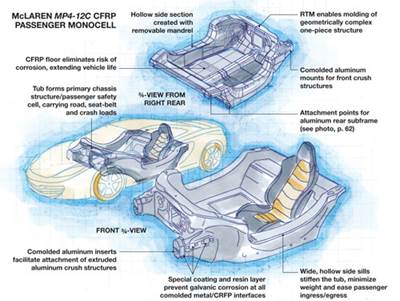

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read More

.jpg;maxWidth=300;quality=90)