Paris Air Show 2013: A century of aircraft progress

Torrential rains couldn’t dampen the spirit of innovation or stop the flood of business aerospace announcements.

The 100th year and 50th edition of the Paris Air Show, held June 17-23 at Le Bourget, kicked off with fireworks, provided not by the show organizers but by some fearsome lightning storms. Yet, despite the forte pluie that drenched visitors on opening day and at intervals throughout the week, the massive and multifaceted show and its 2,215 exhibiting companies from around the globe attracted hundreds of thousands of visitors. HPC was among them and brought home the following wealth of aerospace industry announcements and news of aircraft technology developments.

Big Boeing news

Major announcements included news of The Boeing Co.’s (Chicago, Ill.) new 787 Dreamliner version, the 787-10. Scott Fancher, Boeing’s VP and general manager of airplane development, said at a press conference that the new model will be 18 ft/5.5m longer than the 787-9 version (now in final assembly) and will transport 300 to 330 passengers up to 7,000 nautical miles/12,964 km, a distance that Boeing says covers 92 percent of the world’s twin-aisle routes and city pairs. According to Fancher, the new version will be 25 percent more efficient than today’s similarly sized aircraft — thanks to a combination of the larger size, engine configuration and high-efficiency wing design — and he claimed it will be the most efficient jetliner in history. The design phase is underway, and flight-testing is anticipated by 2017, with first delivery in 2018. The 787-10 reportedly will compete against Toulouse, France-based Airbus’ A350-900 and -1000 versions. The customers seemed pleased; commitments for 102 aircraft were announced at the show, including Air Lease Corp. (Los Angeles, Calif.), which signed up for 30 aircraft. On the docket at the same press conference was the revamped Boeing 777, or 777X, which will be introduced with a larger “4th generation” composite wing. Fancher says the new wing is based on the 787’s wing design and will be made with the same materials and aero characteristics.

Airbus A350 airborne

For its part, Boeing’s rival, Airbus, diverted its first flying A350 XWB to the show on Friday, June 21, (see photo) during its third test flight for a dramatic wheels-up flyby. The aircraft had completed its first flight only seven days previously. The flyover was witnessed by French president François Hollande, who arrived at the airfield aboard an Airbus Military (Barajas, Spain) A400M aircraft from France’s Vélizy - Villacoublay Air Base, southwest of Paris. The A400M also performed daily flight demonstrations during the show.

According to Airbus, it booked $68.7 billion (USD) in orders for 466 aircraft at the show. That figure comprised memoranda of understanding for 225 aircraft and firm purchase orders for 241 more, worth $39.3 billion. The company received 69 orders or commitments for the A350 from four customers. An eye-opening order for 20 A380s came from Doric Lease Corp. (Offenbach am Main, Germany), worth $8 billion.

Russian renaissance

One of the biggest stories at the show was the reemergence of Russian aviation, clearly demonstrated by the large number of Russian aircraft companies that were present. A huge chalet housed United Aircraft Corp. (UAC, Moscow, Russia), an umbrella company that includes 23 companies and design bureaus; among them are Moscow-based Sukhoi Co. and IRKUT Corp. In a formal ceremony on Tuesday morning, the first Sukhoi SSJ100 Superjet for a Western customer was presented to Mexico City-based airline Interjet. During the air show, Sukhoi’s Su-35 Flanker-E fighter jet put on a stunning aerobatic display. The powerful twin-engine, long-range warplane, developed for the Russian Air Force, demonstrated low-speed handling and high-speed maneuverability; the aircraft’s composite airframe materials allow additional fuel storage.

Later that day, IRKUT held a press event to showcase its narrow-body MS-21 commercial jet. Its 30 percent composite airframe includes a vacuum-infused wing produced by IRKUT’s AeroComposit center of excellence, using Hexcel’s (Stamford, Conn.) HiTape dry carbon out-of-autoclave reinforcements and automated layup. The design is frozen, the aircraft has entered production and testing is already underway, with first flight scheduled for 2015. AeroComposit’s president, Anatoly Gaydanskiy, says the composite wing was designed with a high aspect ratio to improve aero performance, with an eye to the lightest possible weight for the aircraft: “We have made substantial progress on new technology,” he said, noting that five wing prototypes have been produced and tested. The sleek interior (see photo) was designed by Zodiac Aerospace (Plaisir, France). According to Oleg Demchenko, IRKUT’s president, “The MS-21 provides more passenger personal space than the 787 or the A350 XWB.” IRKUT has 135 firm orders for the aircraft and predicts marketplace success.

Antonov (Kiev, Ukraine), another aircraft OEM that went through some tough times after the breakup of the Soviet Union, held its own press conference to describe its 67-year history and its efforts to bring new models to market. Known for the largest airplane in the world, the An-225 heavy lifter, Antonov is continuing R&D, says company president Dmytro Kiva. Efforts include expanding the company’s use of digital design tools in general and, more specifically, promoting new designs. Among them are the An-148 and An-158 regional jets and their variants, all of which incorporate significant percentages of composite materials and the An-70 cargo aircraft (see photo). The latter has 10 metric tonnes (22,4046 lb) more payload capability than the Airbus A400M and can operate from short and unimproved airstrips in rough conditions, Kiva claims.

New VTOL and STOL aircraft

At its first Paris Air Show, Aeros Corp. (Montebello, Calif.) was on hand with a scale model of its Aeroscraft cargo craft, with vertical take-off and landing (VTOL) capability. A proprietary helium compression system makes the airship lighter than air during flight and heavier than air on the ground, eliminating the need for tethering and ballasting. A proof-of-design, half-scale prototype recently flew, says John Kiehle, public relations manager for the company, and Aeros is now offering the variable-buoyancy airship to commercial operators in two sizes: the first is capable of carrying a payload of 66 metric tonnes/145,500 lb; and the second can handle up to 250 metric tonnes/551,150 lb. The goal, says Kiehle, is FAA certification by 2016, and Aeros plans to produce 24 airships by that date. The company intends to lease rather than sell the craft and would act as operator. Target markets include the oil and gas industry, wind energy (for transport of blades and towers) and humanitarian aid.

Another unusual aircraft, the Project Zero technology demonstrator, attracted a lot of attention at the AgustaWestland (Amsterdam, The Netherlands) static display. The exotic unmanned tiltrotor — two tilting fans within a 40-ft/12m wide blended wing fuselage — is the result, says AgustaWestland’s VP of R&D, James Wang, of a design brief that called for something “radically different, even impossible!”

Designed in six months by a 20-person team, Project Zero has an electric propulsion system in which the motor shaft acts as the rotor shaft. The blades, support struts, spinner and circular shroud/nacelle were fabricated from carbon/epoxy composites by partner Uchida Carbon Composite Technology (Saitama, Japan). The aircraft’s composite skins were molded by Lola Composites (Cambridgeshire, U.K.). “Everything on it had never been done before,” Wang claims, adding, “There has never been an electrically powered VTOL aircraft.” Project Zero has flown in Italy, both tethered and untethered, but, according to Wang, it serves only as a test bed for technologies that might eventually earn their way onto other company projects. Notably, AgustaWestland is developing the AW609, the civilian version of Boeing’s V-22 Osprey tiltrotor.

Flaris (Podgórzyn, Poland), an offshoot of a family-run company called Metal-Master, surprised everyone at the show with the introduction of a previously unannounced very light jet, dubbed the Flaris LAR-01. The carbon composite single-engine five-seater, complete with detachable wings and short takeoff and landing (STOL) characteristics, has already entered testing, and the company is aiming for U.S. Federal Aviation Admin. (FAA) certification by 2015. According to the company Web site, composite components are produced by tier partners using prepreg.

More unmanned aviation

Unmanned aerial vehicles (UAVs) were present at many displays, but one of the most eye-catching was the AR.Drone 2.0 made by Parrot SA (Paris, France). Controlled by a smart-phone app, the tiny UAVs, about 20 inches/508 mm on a side with a total weight of no more than 420g/14.8 oz, have four rotors driven by battery-powered electric motors and are made with a combination of carbon fiber tubing and fiber-reinforced polyamide. Foam is used to protect the rotors for “indoor” applications. Target customers appear to be aerial photographers and anyone who wants a personal VTOL aircraft for play.

Iomax (Mooresville, N.C.) demonstrated its ArchAngel border patrol plane based on a Thrush 710P crop-duster aircraft. Of interest to the composites industry are the “pods” that attach to the underside of the aircraft, outfitted with mission-specific equipment, such as surveillance cameras. Although stock versions are made of metal, the flexible pods are available in composite versions for weight savings. Iomax reports that the pods and pylon structures that attach them to the airframe are fabricated by Cobham Composite Products (San Diego, Calif.).

Openings and expansions

Business announcements of interest to the composites community included one from Tier 1 supplier GKN Aerospace (Worcestershire, U.K.), which reported that it would open a new advanced engineering center in Bangalore, India, in August. The center will provide engineering resources to the company’s international aerospace projects, across all areas of expertise, and will add skilled individuals to strengthen the company’s workforce. In addition, its newly integrated Engine Systems operation (the former Volvo Aero, acquired in 2012) has made GKN one of three leading engine component suppliers to international aerospace companies, which diversifies the company’s portfolio of projects and clients in the current era of defense spending cuts. It supplies fan/compressor cases and structural parts to virtually every major jet engine program. Also on the company’s advanced composites radar is widespread improvement of its composites manufacturing processes, including faster automation, alternative (out-of-autoclave) curing methods and rapid nondestructive testing (NDT) methods to improve productivity. GKN also announced that it plans two additional automated fiber placement machines at its Bristol, U.K., facility to handle composite part ramp-up rates.

ITT Exelis Aerostructures’ (Salt Lake City, Utah) VP and general manager, Mike Blair, spoke with HPC about his company’s first appearance at the show as a standalone business. With the first phase of its expansion in Salt Lake City now fully operational, the company is prepared to leverage its heritage experience and expand into new programs and markets, with a strong focus on lean and cost-effective manufacturing, says Blair. The recently commissioned 250,000-ft2 (23,226m2) facility (with room for expansion) is near the airport. It is equipped with an automated tape laying (ATL) machine from MAG IAS (Hebron, Ky.), automated fiber placement capability, a new 15-ft by 50-ft (4.6m by 15.4m) autoclave, seven large machining centers built by Breton SpA (Castello di Godego, Italy) and braiding and resin transfer molding (RTM) equipment. Unveiled at the show was an ITT Exelis exclusive joint venture with Bodair (Oupeye, Belgium) for high-speed filament winding of carbon/epoxy rods and struts for aircraft programs. The proprietary equipment, designed by Bodair, reportedly can produce 40,000 parts per year, added Blair.

Composites in jet engines

Inside the six expansive exhibit halls, jet engines and their components attracted crowds. At the Safran SA (Paris, France) exhibit, the company announced a long-term contract with Hexcel for the supply of carbon composite materials for the LEAP-1 jet engine, a development of CFM International, a 50/50 joint venture between Safran (formerly Snecma) and GE Aviation (Evendale, Ohio). Under the contract, Hexcel will supply HexTow IM7 carbon fiber to be used in the manufacture of all LEAP-1 fan blades and containment cases, including those for the Airbus A320neo, the Boeing 737MAX and the Beijing-based Commercial Aircraft Corp. of China’s Comac 919. Hexcel also will supply carbon prepreg for the manufacture of A320neo nacelles.

Safran reiterated its commitment to composites with a presentation titled “How composite materials are revolutionizing aviation.” The company’s Composites Research Center, under construction at Safran’s Villaroche, France, facility, will conduct R&D on new resins and fibers and optimized curing methods, and it will design new parts for engines. One example was on display at the booth: a ceramic-matrix composite (CMC) low-pressure turbine blade designed for the LEAP-1, which is undergoing tests on demonstrators. Safran has partnered with Albany Engineered Composites Inc. (Rochester, N.H.) to produce woven 3-D preforms for carbon fiber fan blades made in an RTM process for the LEAP engine program. Demand for the blades is rising, and Albany is in the process of building a new manufacturing facility in New Hampshire to produce the parts in greater numbers.

Meanwhile, GE Aviation confirmed at the show that its GE9X engine for the Boeing 777X will likely include CMC materials as rotating components in the engine’s second stage, the hot segment where exotic metal alloys are typically employed. GE says the switch to CMCs could reduce fuel burn, thanks to lighter weight and improved thermal performance — that is, air would not have to be diverted for cooling CMC parts, as required for metal components.

And much more

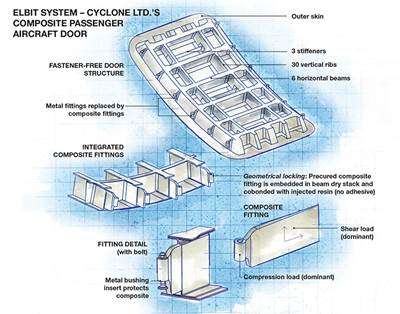

Elbit Systems – Cyclone Ltd. (Karmiel, Israel) showcased its cost-reduced “one-shot” RTM method for producing a fastener-free monolithic composite control surface without a core. Using dry carbon fiber materials and epoxy resin, the patented method embeds and geometrically locks composite fittings into the main structure, which then are cocured during processing. The process eliminates assembly of structural parts, says Eitan Cohen, senior director of business development and marketing for the company, and provides a highly efficient and fastener-free aerodynamic surface. Elbit Systems also has developed a way to produce composite winglets in a similar manner to replace metal for a 30 percent part weight savings. (For more on this process, see “Cutting the cost of integrated composite aerostrutures,” this page.)

Despite its comparatively small size, Corse Composites Aéronautiques (CCA, Ajaccio, Corsica) showcased 30 years of experience as a risk-sharing partner in the development of complex aerospace composites. Prominently on display at its stand were several types of composite landing gear doors and pylon fairings for the company’s major OEM customers, including Airbus, Safran and Dassault Aviation (St. Cloud, France).

MTorres (Torres de Elorz, Navarra, Spain) announced that its recently acquired subsidiary, Pacifica Engineering Inc. (Bothell, Wash.), now MTorres’ U.S. headquarters, has expanded with a new assembly and integration facility in Everett, Wash. It provides more capacity for tooling design/build, machines for aeromanufacturing, and it will house assembly, test, inspection and delivery functions for MTorres machines shipped from Spain to North American customers.

At the Belgian pavilion, Acrosoma (Lokeren, Belgium), a panel manufacturer whose products have been used in truck trailers, housing and more, announced that it has teamed with tooling and fixturing specialist Micado Smart Engineering GmbH (Lienz, Austria). Micado uses Acrosoma panels to create tool fixtures for composite part trimming and finishing.

Not a composite itself but an aid in composite fabrication, Skyflex antichafe sealing material, produced by W.L. Gore & Assoc. Ltd. (Dundee, U.K., and Newark, Del.) is made of expanded polytetrafluoroethylene. The tape’s high elongation and flexibility enable it to conform to variable gaps between mechanically fastened composite parts. Chemically inert and fuel-/chemical-resistant, it provides vibration damping and abrasion protection for laminates in service.

Related Content

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Cutting the cost of integrated composite aerostructures

A unitized all-composite aircraft door concept is realized in one shot with no fasteners.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More