Out of Autoclave

Market Outlook: Fiber-reinforced phenolics

When it comes to corrosion resistance and low smoke toxicity, it's hard to beat fiber-reinforced phenolics. Manufacturers look for new applications for this often overlooked material.

Read MoreSuddenly, automotive composite production abounds

There are at least eight composites manufacturing systems targeting high-volume automotive production.

Read MoreComposites evolution, big and small

We like to focus on the Next Big Thing in composites, but everyday processes need attention too.

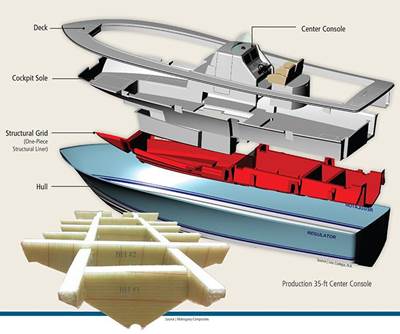

Read MoreThe structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Read MoreAn impec-able bike frame: Handmade by machine

Long on technology firsts, this optimized, automated manufacturing process produces nothing short of the “perfect” bike frame.

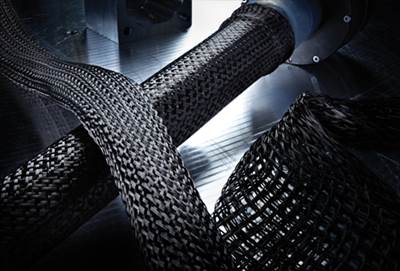

Read MoreNext-generation braiding for next-gen bike

When Grenchen, Switzerland-based Bicycle Manufacturing Co. (BMC) decided to braid the tubes for its impec racing bike frame, the use of carbon fiber and the complex tube designs and shapes prompted the use of radial braiding technology from August Herzog Maschinenfabrik GmbH & Co. KG (Oldenburg, Germany)

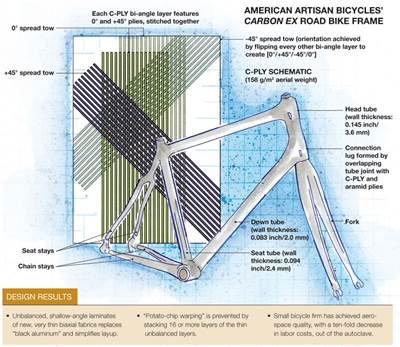

Read MoreBi-angle fabrics find first commercial application

Bicycle manufacturer sees dramatic productivity gains using unbalanced fabrics conceived at Stanford University and manufactured by Chomarat.

Read MorePressurized Water-based mold temperature control comes to composites

HPC editor-in-chief Jeff Sloan details recent testing that gauged the comparative efficiency of electric, oil-based and water-based mold temperature control systems.

Read MoreUnderground storage tanks: Rehabilitation without excavation

An unusual “lost-core” composite adds double walls protection to noncompliant tanks without excavation.

Read MoreSPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

Read More