Processes

Leveraging towpreg to reduce the cost of CMC

High-denier, spread-tow Nextel 610 fiber and novel alumina matrix enable AFP production of Ox-Ox ceramic matrix composites.

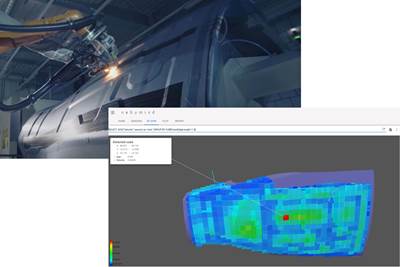

Read MoreUsing sensor data to improve composite parts and processes

nebumind software builds digital twins from manufacturing data to trace defects, compare manufactured parts, qualify processes, develop tolerance windows for process monitoring and more.

WatchZortrax develops groundbreaking 3D Printing technology

High-performance parts are made out of two blends of PEEK filament via dual extrusion on Endureal industrial 3D printer.

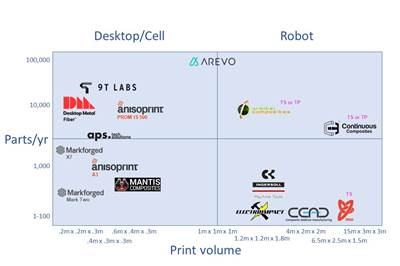

Read MoreNew 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

Read MoreTechsil, Panacol offer Vitralit adhesive for filament winding

The transparent one-component epoxy adhesive and curing system is ideal for carbon fiber or glass fiber filament winding.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

Read MorePoly Glass reports manufacture of 60-foot infused monohull boat in India

The ZenCat commercial vessel features a 60-foot vacuum-infused FRP hull enabling weight reduction and fuel savings.

Read More3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

Read MoreComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

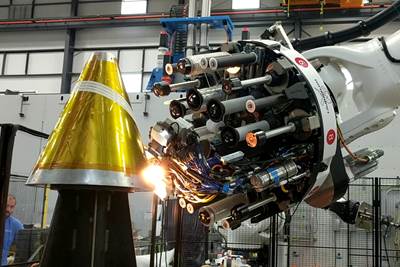

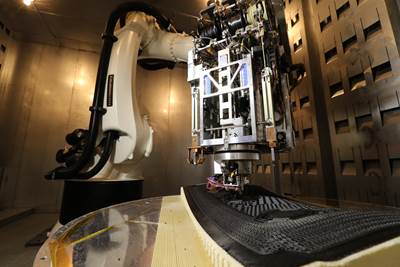

Read MoreCombining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

Watch