Processes

Thermwood demonstrates vertical layer print additive technology

The new approach for large scale 3D printing was validated via Thermwood’s LSAM system and printed parts up to 5 by 10 by 10 feet.

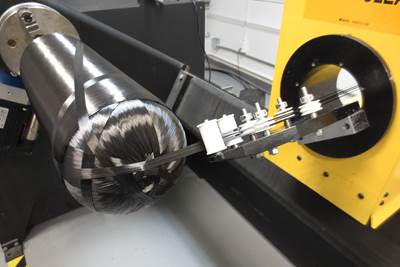

WatchCompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

Read MoreKanfit installs new autoclave, automated cutter to increase composite parts production capacity

Composite parts producer in Israel increases capabilities for composites, 3D printing and hybrid assemblies.

Read MoreAramis optical strain gage targets material and structural testing

Trilion Quality Systems’ non-contact and material-independent measuring system is cheaper, more accurate, less labor/time-intensive and is said to provide 100 times more data.

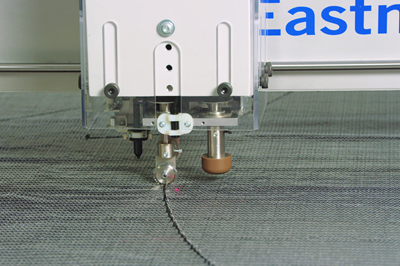

Read MoreAutomated Cutting of Composites Reinforcement Saves Time and Material, Improves Quality

Automated cutting of reinforcement materials is fast, accurate and reliable. It reduces labor costs and material waste and can substantially boost throughput.

WatchUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

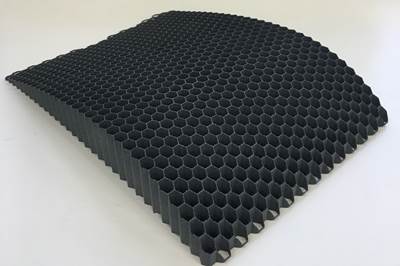

WatchHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreAerojet Rocketdyne to provide ULA Vulcan Centuar launch vehicle's key propulsion

The company will supply its two RL10 rocket engines to power the vehicle’s upper stage, thrusters and composite overwrapped pressure vessels.

Read MorePart 2: Performance and safety benefits of prepregs

Returning with his second installment, Brian Bishop discusses the performance and safety benefits to using prepreg, and the value they can bring to composites fabricators.

Read MoreC-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

Watch