Processes

GKN, Raytheon reach agreement for composite missile canisters

Per the three-year contract, GKN Aerospace will provide Raytheon with 95 Mk30 missile canisters that are manufactured via a filament winding process followed by vacuum infusion.

Read MoreMoi Composites debuts 3D-printed glass fiber boat

Moi used its patented CFM 3D printing technology for depositing continuous fibers impregnated with thermosetting resin to develop MAMBO’s unique design.

Read MoreHow Digital Cutting Technology Reduces Costs and Improves Flexibility

Automated cutting of composites reinforcement and other technical textiles is faster, more accurate and can result in dramatic reductions in material waste and labor. Having the right software is the key to getting the best results.

WatchAI-based software solution improves Enercon's cutting and kitting operations

Plataine's optimization software solution enables Enercon to meet market demand, automate manufacturing processes and significantly reduce production costs and material waste.

Read MoreArevo introduces high-speed AM system, closes Series B financial round

The financing round and high-speed AM system for large continuous carbon fiber composite structures follow Arevo’s 3D-printed bicycle campaign.

Read MoreNedcam adds CEAD AM Flexbot for 3D printing using DSM materials

The two companies will explore new applications in tooling, large-sized and circular end-use parts.

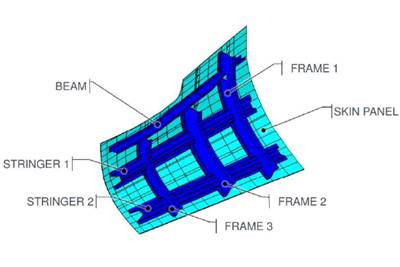

WatchFRAMES: Full-scale thermoplastic composite aircraft rear-end demonstrator

Clean Sky 2 project led by ESTIA-Compositadour will develop enabling technologies for optimum rear fuselage and empennage.

Read MoreComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

WatchOrbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

Read MoreCRP Technology produces composite sensor housing box

Commissioned by IMAL s.r.l., CRP applied its carbon fiber-reinforced Windform XT 2.0 material, which retains an 8% increase in tensile strength and 22% increase in tensile modulus.

Read More