Processes

CSP fine-tunes CF-RTM process, launches production programs

The carbon fiber RTM press will be installed at the CSP facility in Palmela, Portugal in order to run the company's first commercial applications using this technology.

Read MoreVastek Industrial showcases tabletop infrared conveyor oven

Ideal for laboratory testing and low-volume production applications, the D-100 model is highly compact, and ensures edge-to-edge temperature uniformity.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

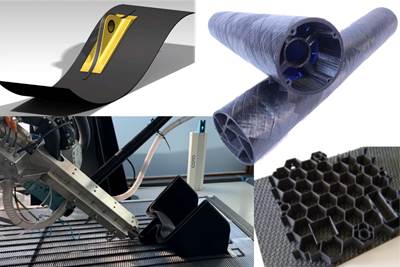

Read MoreFuture composite manufacturing - AFP and Additive Manufacturing

TU Munich symposium explores how these technologies are merging and reviews R&D that is creating a path forward.

Read MoreTech Table: Compression molding machines

CW’s third Tech Table represents compression molding machine data collected from information provided by suppliers.

Read MoreSkoltech optimizes pultrusion process productivity

The institute analyzed the influence of pulling speed on the structural characteristics of L-shaped profiles, analyzing the interconnection between a variety of characteristics.

Read MoreAddcomposites installs AFP-XS at Compositadour and integrates humm3 flash lamp

French technology platform expands access to composites beyond aerospace, while humm3 offers cost-effective dry fiber and thermoplastic tape placement in addition to CF/epoxy prepregs.

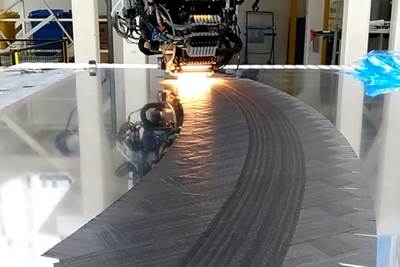

WatchAFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

WatchInfinite Material Solutions presents water-soluble support material for 3D-printing capabilities

AquaSys 180 is compatible with high-temperature thermoplastics and holds an advantage for the Fused Filament Fabrication (FFF) 3D printing process.

Read MoreAltair Inspire Mold simulates injection molding process to optimize manufacturability

Inspire Mold can evaluate manufacturability of new components at the outset of development, complete design iterations faster, reduce cost and other optimization features.

Read More