Processes

Porcher Industries launches new range of flax fiber-based thermoplastic composites for automotive

Composite stiffeners, sold as textiles, are made primarily of flax fibers grown, selected, mixed and woven in France for modern, durable and environmentally conscious applications.

Read MoreTeijin Automotive Technologies to produce pickup box for next-gen Toyota Tundra

One-piece compression molded composite pickup boxes — in addition to the tailgate — will be produced at the company’s Seguin, Texas, facility in three size options.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

WatchTechnology Marketing acquires SR Composites’ IP rights for Sprayomer Technology

Technology Marketing to leverage the accelerated adoption of reusable vacuum membranes and bags in the composites industry.

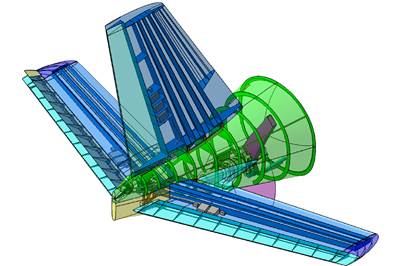

Read MoreMulti-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

WatchAtlas Copco’s GHS VSD+ vacuum pump range offer Industry 4.0 functionalities

Variable speed-driven, oil-injected screw vacuum pumps are well suited for the infusion process, complete with 15% smaller footprint, integrated HEX@TM controller and optimized performance.

Read MoreAnisoprint signs MOU for space-based continuous fiber 3D printing

Continuous fiber co-extrusion (CFC) technology capacities in orbit and for the deployment of additive manufacturing have been demonstrated and validated.

Read MoreHigh-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

Read MoreBM Composites announces the launch of the Linx 30 Superyacht Tender

The first custom tender brand designed and made in Mallorca, Spain, highlights the customizable Linx 30, a carbon fiber infused superyacht with 30-40% improved fuel efficiency.

Read MoreHypertherm announces release of ProNest 2023 CAD/CAM nesting software

ProNest 2023 focuses on improving its automated Industry 4.0 functionalities and reducing cutting waste, ultimately giving users a more holistic operations perspective.

Read More