Processes

Stratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

Read More3D printing on the moon: Anisoprint chosen for Start-up Space Program

During SSP, Anisoprint will work to develop composite fiber 3D printing in close-to-zero gravity conditions.

Read MoreJoby Aviation advances toward FAA certification, highlights Toray prepreg and Coriolis AFP machines

Joby Aviation aims for FAA Part 135 certificate by end of 2022 and launch of commercial service by 2024 as it completes first production-intent aircraft from its pilot manufacturing facility; composites play a key role.

Read MoreBASF, L&L Products collaborate on battery protection for the 2022 Ford F-150 Lightning

Continuous Composites Systems and polyurethane pultrusion system reduces crossmember size while providing strength, stiffness and rigidity to withstand high loads.

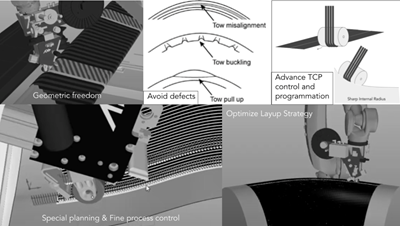

Read MoreAddcomposites path-planning, simulation and defect detection platform for AFP

Purpose-built OLP software platform, AddPath, now supports multiple AFP tools, enabling end users to use their own existing hardware.

Read MoreUMaine Composites Center 3D prints logistics vessel for U.S. Department of Defense

Two 3D-printed vessels capable of transporting two shipping containers and a Marine rifle squad with three days of supplies mark groundbreaking composite manufacturing milestone.

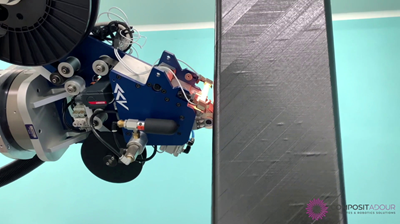

Read MoreAFP-XS platform demonstrates rectangular tube manufacture

Addcomposites collaborated with MBDA and Compositadour to produce lightweight, stiff and weatherproof components that are electrically insulating, chemically resistant and dimensionally stable.

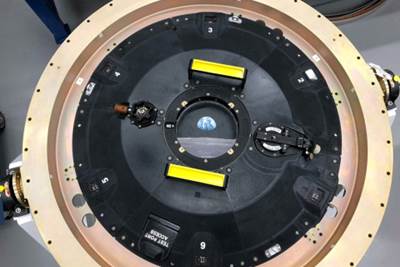

WatchAddcomposites brings multi-tow AFP system to the composites market

The automated system offered by Addcomposites is adaptable to complex shapes and enables multi-format and multi-material type preforming.

Read MoreHypetex creates colored carbon fiber covers for IQOS tobacco heating devices

The U.K. manufacturer and supplier of advanced materials coordinated all aspects, from initial concept to final solution, including a fully optimized production process.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read More