Processes

Dynamic PRC racing team uses 3D printing to create DP13 autonomous race car

The new vehicle prototype uses fiber-reinforced 3D printing material formulated by the RadiciGroup to maximize mechanical and aesthetic performance.

Read MoreAzco Corp. presents servo-controlled unwind and rewind unit

The cantilever-designed unit is able to transfer between unwinding and rewinding via a change in the direction, torque and speed, controlled by an HMI touch screen.

WatchMonash Motorsport constructs FSAE autonomous, electric vehicle with ATL Composites materials

Composite are incorporated into the vehicle’s monocoque chassis, aerofoils, aerofoil endplates and other components to suit high aerodynamic loads, minimize mass and enhance efficiency for the globally competitive team.

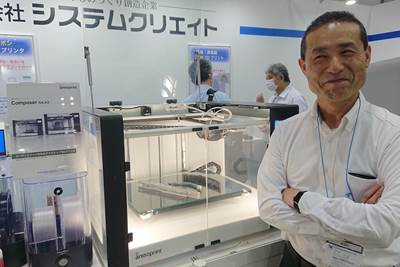

Read MoreAnisoprint expands global presence, announces exclusive partnership with Systemcreate

Systemcreate is a technology provider that will now exclusively distribute Anisoprint’s continuous fiber coextrusion technology and Composer system in Japan.

Read MoreHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MoreAIM3D evaluates potential of composite extrusion modeling 3D printing test with PA6GF30

Glass fiber-reinforced polyamide 3D-printed test specimens proved higher tensile strength, cost effectiveness compared to injection molding and conventional 3D printing processes.

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

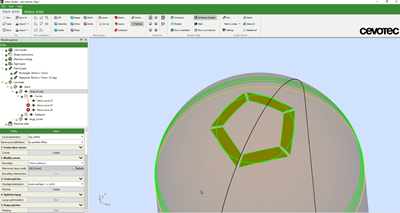

WatchCevotec integrates trapezoid-shaped patches into FPP Artist Studio software

Patch Artist module facilitates more even distribution of patches along tight curves during pressure vessel dome reinforcement, resulting in an optimized laminate thickness.

WatchFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read More