Processes

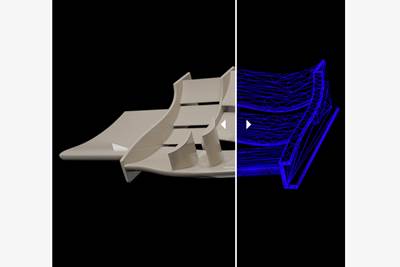

CF3D technology developments for continuous fiber AM applications

Studies conducted by Continuous Composites, Lockheed Martin and the Air Force Research Laboratory advance aerospace applications of continuous fiber additive manufacturing.

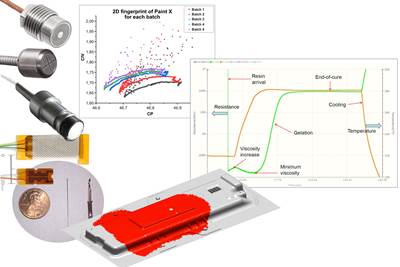

Read MoreSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

WatchPredicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

Read MoreKeyland Polymer, polySpectra combine photopolymers, powder coatings to advance 3D printing

UVMax powder coatings provide a spectrum of surface color and texture possibilities, while COR Alpha photopolymers have been refined for durability.

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

WatchSABIC, Dongfeng Motors produce composite truck-mounted toolbox

Thermoformed glass fiber-reinforced PP laminate inserts are overmolded with Stamax resin for a 30% lighter part.

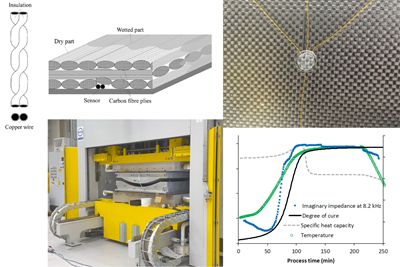

Read MoreNational Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program

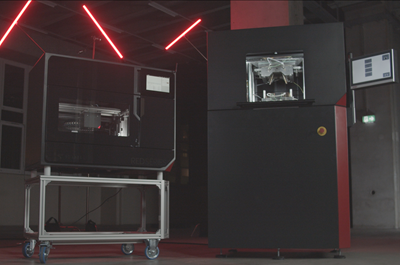

Read More9T Labs raises $17 million in Series A funding to advance carbon fiber 3D printing

The investment will help fully commercialize the company’s Red Series software tools, 3D printer and molding equipment to lead the way in the production of sustainable, high-performance CFRTP parts for end-use applications.

Read MoreMiddle River Aerostructure Systems displays aeroengine nacelle using AFP and RTM composites

Highlights technologies and manufacturing processes that enhance aeroengine operating efficiency while reducing fuel consumption and noise.

Read MoreRoboze reveals ceramic-filled Helios PEEK 2005 filament to the 3D printing sector

Ceramic reinforcement proves an ideal candidate for applications that require lightness, mechanical strength, heat resistance and highly complex geometry specifications.

Read More

.jpg;maxWidth=300;quality=90)