Processes

Fortify Flux 3D printers optimize fiber alignment, enhance properties for tailored composites

Systems combine mixing magnetics and digital light processing (DLP) 3D printing to enhance composite microstructures and develop high-performance, low-cost components.

Read MoreMAMBO tests the waters for 3D printing large marine structures

With its MAMBO boat, Moi Composites demonstrates use of its continuous fiber 3D printing technology for customized, automated production for the boating industry.

Read MoreCEAD and Belotti make large-scale additive composites manufacturing accessible for industry

Strategic partnership combines expertise of additive and subtractive manufacturing into single hybrid solution: BEAD.

Read MoreEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

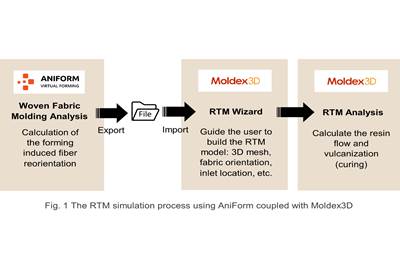

ListenAniForm, Moldex3D develop interface tool for more accurate RTM prediction analysis

Interface enables users to consider forming-induced fiber reorientation in the RTM simulation model for a more accurate representation of the flow domain.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

Read MoreCovestro introduces 3D printing material made from recycled PET

Glass fiber-filled rPET suitable for high performance and structural applications using 3D pellet printing/fused granulate fabrication (FGF).

Read MoreFAA-funded MSU research program to address resin infusion needs in aerocomposites market

Phase I of the Mississippi State University Advanced Composites Institute’s multi-year program seeks industry feedback to identify market satisfaction gaps.

Read MoreContinuous Composites, Saint-Gobain collaboration advances CF3D technology

Saint-Gobain to bring CF3D production systems in-house, with a focus on certifying the patented technology for use in commercial aerospace applications.

Read MoreDevelopment of composite isogrid structures using innovative deposition technology

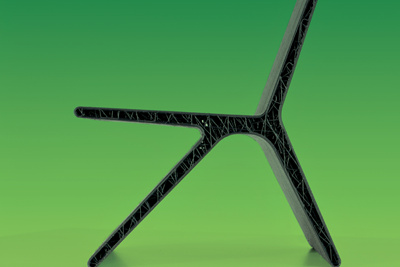

Versatile robotic system integrates in-line towpreg impregnation, offering reduced-cost, high-performance isogrid structures for a variety of industries.

Read More