Processes

Antich and Sons develop composite yarn-spinning technique for 3D-woven preform production

Culmination of a three-year project with AMRC which focused on creating stabilized, near-net shape preforms of variable thickness with efficient material use for aerospace and automotive.

Read MoreThermwood expands LSAM product line availability

Large dual gantry print and trim machines for 3D-printed thermoplastic composites offered in 15-foot width model, with wider gantry design and range of print core, print head options.

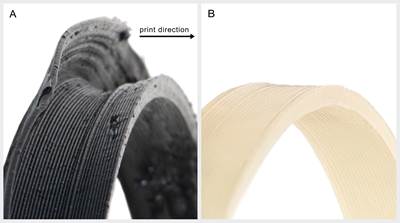

Read MoreNatureWorks Ingeo 3D700 biopolymer reduces LSAM warpage, minimizes print failures

Testing by NatureWorks’ global partners demonstrates a shrink rate less than 0.25% in printed parts and obtainable lower print temperatures due to optimized melt viscosity and microstructure.

Read MoreIncreasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

Read MoreFortify expands fiber-reinforced photopolymer 3D printing line for end-use part applications

Company adds new FRP printers and open access software to enable new advanced materials, including Flux Core and Flux 3D.

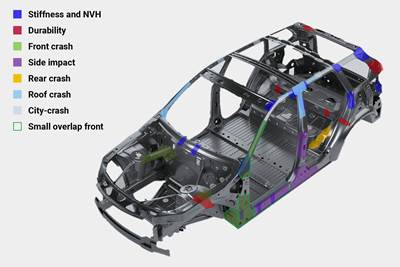

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read MorePurdue University to establish Thermwood LSAM research laboratory

Industry-funded research to pursue large-scale composite thermoplastic additive manufacturing, with the goal of providing services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications.

Read MoreHuntsman Advanced Materials resin systems meet composite pressure vessel requirements

Araldite resin systems cover wet and towpreg filament winding and RTM manufacturing processes for increased productivity and greater part consistency.

Read MoreBest practices in the CNC machining of composites

Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable.

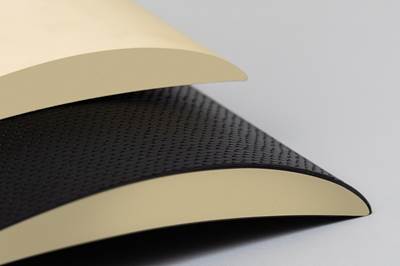

Read MoreHuntsman PU resin systems enable lightweight sandwich construction for automotive

Vitrox RTM and Rimline FC polyurethane systems to advance lightweighting, design freedom and simplified manufacturing opportunities.

Read More