Processes

Hexion partners with Rassini for composite leaf spring application in new Ford F-150 model

Pickup truck model’s hybrid rear suspension is supported by a composite helper spring which uses Hexion’s epoxy resin system and is processed via HP-RTM.

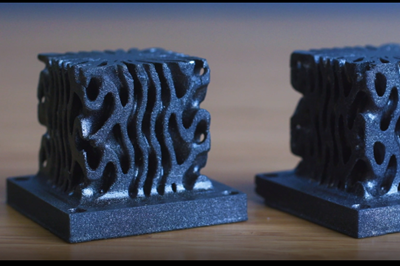

Read MoreCRP Technology highlights Windform RS composite material for powder bed fusion processes

Polyamide-based carbon fiber-filled composite provides enhances functionality, flexibility and speed in developing intricate 3D-printed parts.

Read MoreFortify, Roger Corp. partner to develop 3D-printed dielectric material systems

Combination of low-loss material systems and the Flux 3D printer series’ advanced composite processing capabilities augment radio-frequency device manufacture.

Read MoreElectroimpact launches plug-and-play AFP system

Automation and automated fiber and tape placement specialist Electroimpact has introduced Scorpion, a new modular plug-and-play automated fiber placement (AFP) system designed for research and laboratory applications.

WatchOerlikon Balzers launches new line of diamond coatings

Oerlikon Balzers has introduced its new Baldia portfolio of diamond coatings machining and drilling highly abrasive materials.

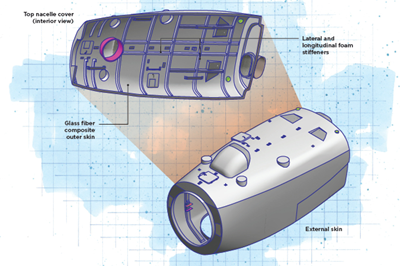

Read MoreOptimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

Read MoreBraskem, Vartega launch new carbon fiber recycling program for 3D printing filament

Carbon fiber-reinforced polypropylene (CF-PP) filament is made from 100% recycled carbon fiber to leverage recycling capabilities and plastic waste elimination.

Read MoreArevo debuts custom, 3D-printed composite scooter

Scotsman is a direct-to-consumer, tailor-made electric kickscooter with continuous carbon fiber/thermoplastic unibody frame, handlebars, stem and baseboard.

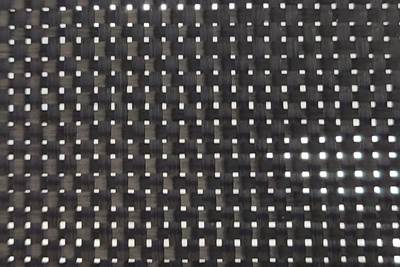

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreDesigning a versatile, multi-material EV battery enclosure

Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.

Read More

.jpg;maxWidth=300;quality=90)