Collins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Building a sustainable future is an imperative as aircraft manufacturers and airlines commit to reducing their carbon footprint. To support this industry-wide advancement, Collins Aerospace (Charlotte, N.C., U.S.) has introduced new and redesigned products to reduce energy usage, decrease aircraft weight, accelerate airframe production and improve overall aircraft quality. Through the use of thermoplastic composites, Collins is driving sustainability in new and exciting ways, including aircraft parts that reduce energy consumption during manufacturing and decrease aircraft weight to lower fuel burn, which in turn provides cost savings for the customer while lowering carbon emissions. These parts have the potential to provide:

- Up to 50% weight reduction compared to metallic structures and 20% lighter than thermoset structures.

- Up to 80% reduction in manufacturing cycle time compared to thermoset composites.

- Up to 100% recyclability at the end of the part’s lifecycle.

Augmenting continuous compression molding in Almere

In November 2021, Collins Aerospace acquired thermoplastic composites structures leader Dutch Thermoplastic Composites (DTC, Almere, Netherlands), with decades of experience as well as current production of more than 2,000 unique part numbers. Now, Collins Aerospace Almere has reportedly set a new record by producing its largest one-piece thermoplastic composites part ever — more than 7 meters long and roughly 60 centimeters wide.

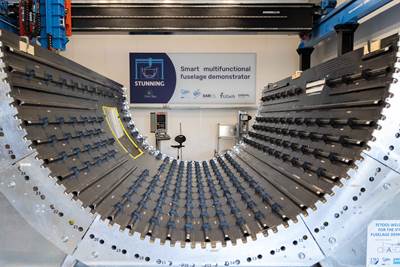

Thermoplastic composite raceway produced by Collins Aerospace Almere for GKN Fokker’s pre-equipped cable tray in the MFFD lower fuselage. Photo Credit: Collins Aerospace

This thermoplastic composite raceway has been supplied to GKN Aerospace (Hogerheide, Netherlands) as part of the Clean Sky 2 STUNNING project, to be incorporated into the lower fuselage floor grid assembly for the Multifunctional Fuselage Demonstrator (MFFD). “The raceway is key to the cable tray system that GKN Fokker will integrate into the MFFD and demonstrates the new assembly philosophy of delivering modules pre-equipped with systems, ready for assembly, to airframe final assembly lines,” Collins Aerospace Almere sales director, René van der Burg, says.

The raceway was manufactured using a carbon fiber-reinforced low melt polyaryletherketone (LMPAEK) tape and a novel continuous compression molding (CCM) process developed in Almere that uses an innovative tooling concept. “Several companies have CCM machines and are also able to produce not just straight blanks but also shaped profiles,” Van der Burg says, “but our approach is unique. We can also produce longer structures, if needed.” This could indeed be of interest for future thermoplastic composite airframes, such as what is being matured in the 8-meter long, 4-meter diameter MFFD. “It serves as a platform for examining the full potential of thermoplastic composites,” Van der Burg notes, “and will help future European airliner production to become faster, more competitive and more sustainable.”

Reducing fuel emissions

“At Collins, one of the biggest areas where we can most dramatically impact sustainability is via the weight and resiliency of our products — so that’s where our Advanced Structures business is focusing its efforts,” David Manten, general manager of Engineered Thermoplastics for Collins Aerospace and founder of DTC, says. “Lighter aircraft equate to lower emissions and a greater ability to reach our industry’s goal of being carbon zero by 2050.”

Thermoplastic composite welding is being demonstrated and advanced by Collins Aerospace in the U.S. for more integrated, lightweight and sustainable airframe structures.

Although thermoplastic composites have been around for decades, Collins Aerospace is expanding its use of this technology and has developed specific technologies that enable the production of larger and more complex parts, as well as the integration of parts through welding. With its latest thermoplastic welding technologies, Collins Aerospace is eliminating the need for thousands of fasteners, which add weight and cost to an aircraft.

As an example, consider the savings that could result if just a small percentage weight reduction were possible for an aircraft seat. For a 200-passenger aircraft, this could add up to a considerable difference, and a corresponding reduction in carbon emissions. This is why Collins Aerospace is currently working to incorporate lighter thermoplastic materials into seats and a variety of other aircraft components.

“Our aerospace customers are depending on us to drive sustainability throughout our supply chain,” Manten says. “Offering lighter weight products by incorporating thermoplastic composites is a great example of how we are meeting this need.”

Decreasing energy consumption

Most of today’s aircraft are manufactured using traditional materials, such as thermoset composites, that consume a massive amount of energy to manufacture. Here, the manufacturing process requires parts to be cured in large autoclaves or ovens that consume considerable amounts of energy to achieve the heat and pressure required for high-quality parts.

In contrast, thermoplastic composites don’t require the same chemical reactions as thermosets so they can be manufactured via more efficient, out-of-autoclave (OOA) processes — like stamping — that greatly reduce energy usage. These same processes can reduce cycle time from hours to minutes while shaping the materials into complex and even multifunctional geometries. Switching from thermosets to thermoplastic composites also adds to energy efficiency as cold storage of thermoset prepreg materials is eliminated.

Recycling capability

There are two hallmarks to the recyclability of thermoplastic composites: durability and reuse. First, thermoplastic composites have a higher resistance to impact and fatigue compared to thermosets, which ensures parts can last longer and is key to future circular economies.

Second, thermoplastic composite products can be recycled at the end of their lifecycle, meaning they can be remelted, reshaped and reused in other industries or for other parts — making them more attractive than current parts that often go into landfills.

“At Collins Aerospace, we don’t just have our eyes on a more sustainable future: we’re building it every day,” Manten says. “Through forward-thinking design, science-based materials selection and improved manufacturing processes, we’re working to reduce aircraft weight for greater fuel efficiency while at the same time incorporating more environmentally responsible materials, like thermoplastic composites, into aircraft components.”

Collins Aerospace Riverside, Calif., U.S. is expanding its capabilities, including new automated fiber placement (AFP) equipment and a welded fan cowl demonstrator by the end of 2022.

Inside the Collins Aerospace Additive Manufacturing Center

The IP challenges of parts made through AM is one of the factors that led Collins Aerospace to launch a new site for additive production. The North Carolina facility supports Collins business units across the country. See video and learn about the new Collins Aerospace additive manufacturing facility.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreRead Next

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More